Products

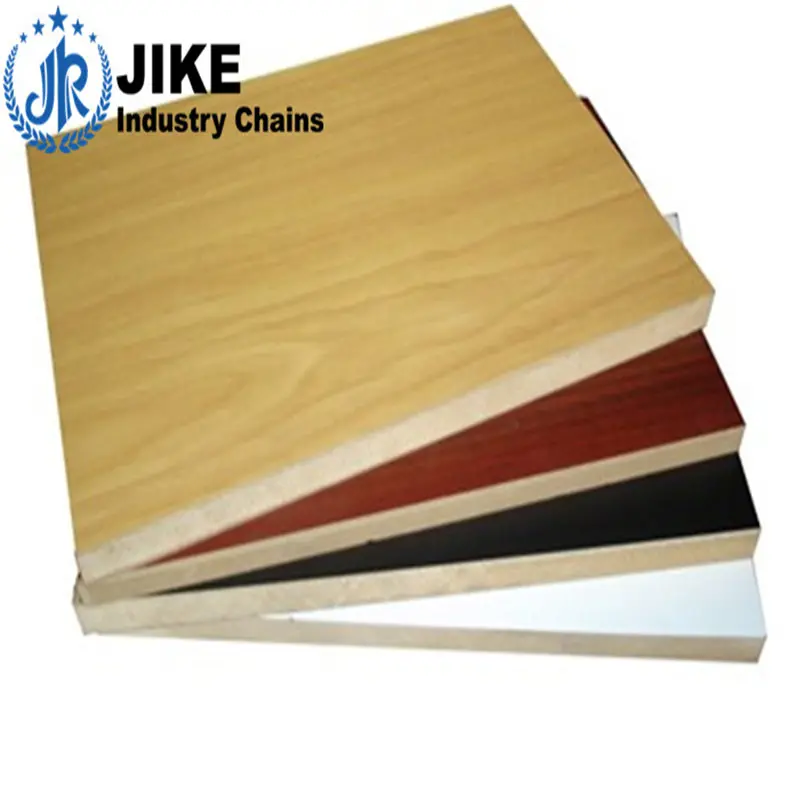

4x8ft 4x9ft kitchen cabinet Melamine MDF board

Melamine MDF board is made from MDF (Medium Density Fibreboard) base board and melamine paper,Formed by high temperature hot pressing.

Its biggest advantages are environmental protection, wear resistance, high temperature resistance, corrosion resistance, waterproof, simple and convenient, variety of patterns and colors ,etc. It is the first choice for customized furniture and indoor decoration .

Block Board 17mm,18mm,19mm,Malacca/Paulownia/Pine/Poplar/Hardwood Core Melamine Faced Good Quality For Sales

We supply many kinds block board, Pine core, Paulownia core, falcata core, etc. We can stick melamine paper or wood veneer on the block board. Anyway if you are looking for the block board for furniture, you find the right product and the right company ,please check our following details and contact us if you need some boards,we must offer you the good quality and good price.

Our block board , with very smooth flat surface. We have a complete production line of machines. When packing, we use plywood to pack, packing tape is 4*8. If you have interest ,we may offer you a sample for you to check the quality.

18mm HPL high pressure laminate fire retardant plywood for furniture and decoration

HPL plywood means high-pressure laminated plywood. HPL decorative layer is made of multi-layer kraft paper pressed under high pressure. HPL laminated plywood is a new type of high-quality plywood that can resist high temperature, moisture and static electricity, mold, chemical corrosion, impact, scratches, and other damage, it is ideal for use in outdoor environments exposed to UV radiation, humidity, and temperature instability, such as coffee shops and kitchen tabletops. Yayou provides HPL faced plywood board in various colors and patterns for our customer, both high-gloss and matte surfaces are available

High Gloss MDF Core Acrylic Faced Coated Board

1)Scratch -resistance and has 2H ,4H available for choice

2)Acid & chemical resistance ,The wine ,soybean sauce & vinegar can not damage surface .

3)Surface with transparent acrylic sheet ,makes color looks 3D and modern.

4)Imported Germany brand PUR -hot -melt -adhesive never delaminating

5)Processing through non-dust -pressing -plant, The finished panel surface no rubbish ,no crack ,no bubble ,Smooth surface ,no orange peel.

Slat wall Panel Melamine MDF For Supermarket Display

MDF slat wall used in supermarkets, retail stores,shops, showrooms as shelves to hang and display small commodities. Attractive facing, durable, multipurpose, cost-effective, can be adjusted left and right, up and down to show commodities.Made from high-quality MDF material, slat wall is durable, long-lasting and can withstand the wear and tear of everyday use. It is also very cost-effective, making it a popular choice for businesses of all sizes.

Door skin/melamine door skin/wood veneer door skin

Door Skin is the use of MDF or HDF or plate as the substrate, the surface Stickers ash,black walnut pear and Sapele wood leather and other natural or Stickers melamine paper, or not posted any veneer and skin, through high tonnage vacuum molding machine, high pres-sure heat in the environment, the use of "forming" or "twice molding" technology produced by the low-carbon, environmentally friendly, beautiful, convenient, no crack, no deformation

the door.

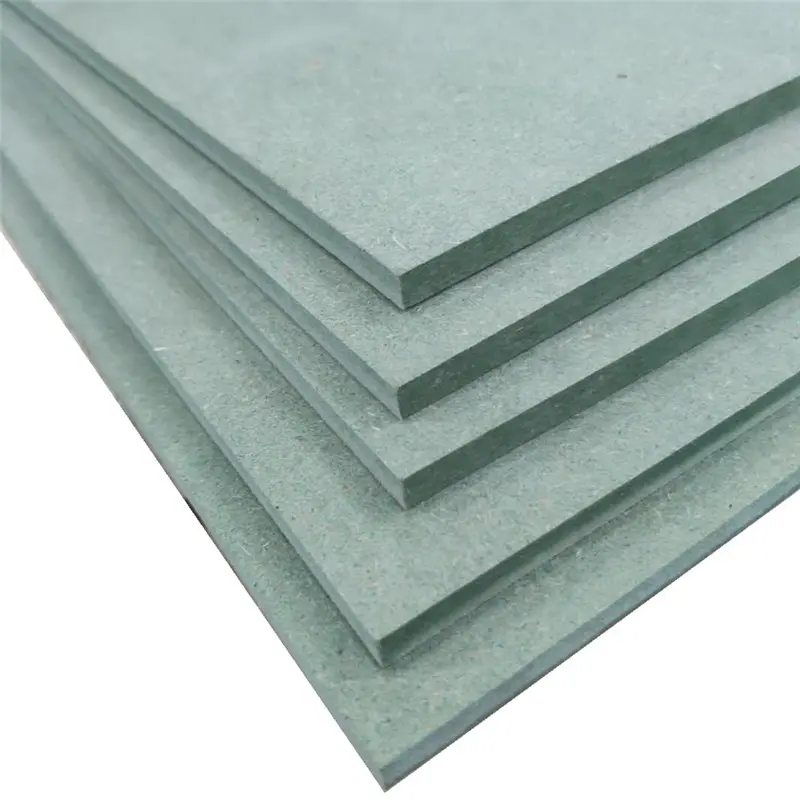

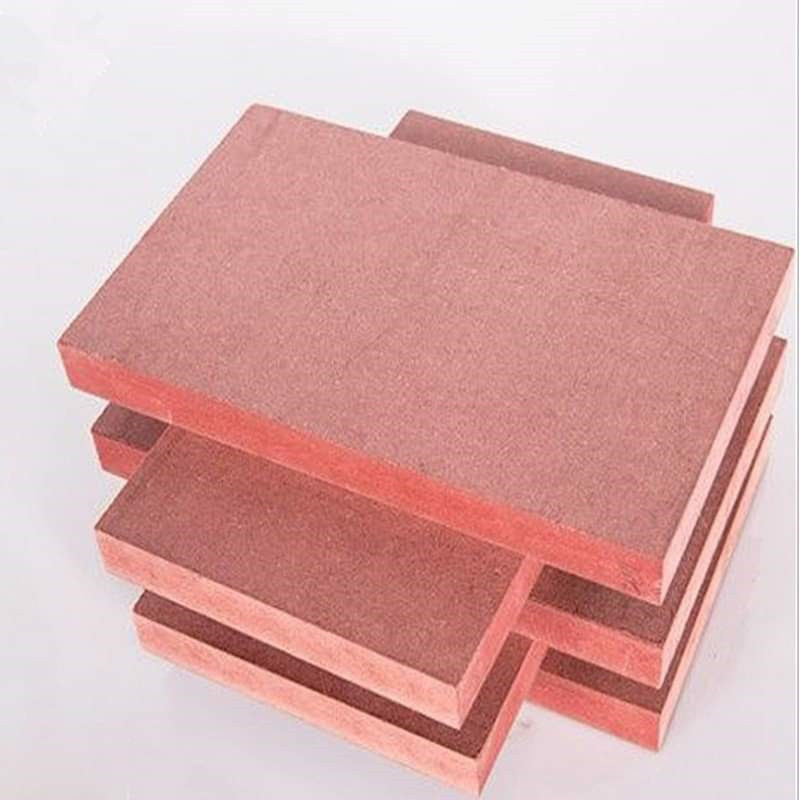

Green 3Mm 6Mm 9Mm 12Mm 15Mm 18 Mm Moisture-Proof Waterproof Moisture MR MDF Board For Furniture

Moisture-resistant MDF is manufactured to be used in environments with risks of moisture or humidity, avoiding the issues that would plague traditional MDF. This is achieved by using a moisture-repellant resin during manufacture, ensuring that an MDF board is not prone to absorbing moisture to the same extent.

High Quality Fire Resistant MDF Fire Rated MDF Board For Kitchen Cabinet

Fire Resistant melamine MDF board is made from FR (Fire resistant ) MDF (Medium Density Fibreboard) base board and melamine paper,Formed by high temperature hot pressing.Its biggest advantages are fire resitstant , environmental protection, wear resistance, high temperature resistance, corrosion resistance, waterproof, simple and convenient, variety of patterns and colors ,etc. It is the first choice for customized furniture and indoor decoration . FR Parameters are as follows : FIGRA0.4MJ(W/S)≤250 ,THR600S(MJ)≤15, SMOGRA(㎡/s²)≤3.

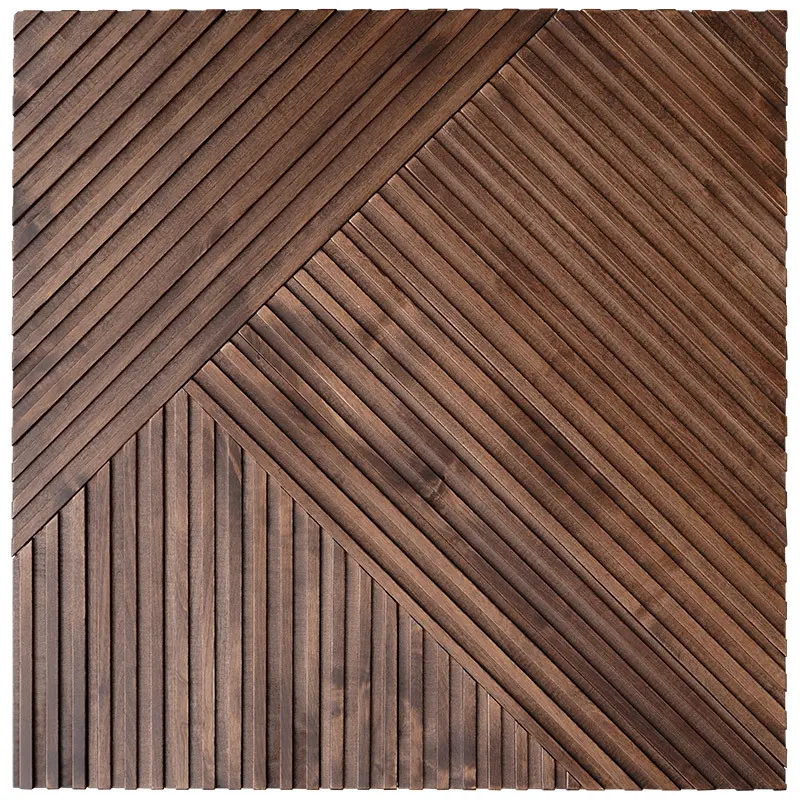

9mm Flexible MDF wall cladding solid oak/pine/elm bending wall board

3D Decorative Wall Panel is a new type of fashionable art interior decoration board. It mainly used in Hotels, Clubs,Home Decoration, Dance Halls, Resorts, Shopping Malls, Luxury Homes, Villas and other decoration projects. Especially suitable for the design of doors, entrances, background walls, TV walls, Pillars, bar, ceiling, exhibition frame. Can replace natural bark, stick,face plate, etc.

MDF Fibreboard for Furniture Indoor Decoration

JIKEWOOD Fibreboards are made from poplar and can be produced at densities ranging from 630kgs/m³ to 1150kgs/m³. It’s a kind of fiberboard. We can directly export the plain board, also can be made into fire-proof, moisture-proof, water-proof and so on.MDF ,HDF is mainly used infurniture, cabinets and so on.

Scaffolding LVL planks for construction

Scaffold-grade lumber is meant to withstand forces not imposed on ordinary, construction-grade wood (which is only two-thirds the capacity of scaffold-grade). Using construction-grade lumber on a scaffold platform not only violates OSHA standards, but is also an unsafe practice and an invitation to a deadly incident.

Laminated Veneer Lumber (LVL) is one of the most common scaffold plank styles used on a jobsite requiring stagging. These laminated planks meet all conformance standards for OSHA and are tested rigorously by their manufacturers

AS/NZS4357.0 certificated structural LVL beams frame

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, frame, studs, beams, rimboard, and edge-forming material. JIKEWOOD LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to Glued laminated timber but with a higher allowable stress.

TJI230 TJI360 TJI560 joists Wooden I joist beam for house building

TJI Joist is a New Wooden Engineering Structural Component . have TJI 230 TJI 360 TJI 560 joists It refers to the solid wood or LVL used as the upper and lower flange, and the plywood structural plate bonding, specifications and performance of stable bearing structural members.The I joist is made up of two main parts: Flange and web these two parts: the first part is the flange flange of the upper and lower Flange, which is made up of solid wood or LVL.The second part is the intermediate Web called the Web(net), the usual material is OSB board.The Flange gets its name from web and flange, which are connected together with high-quality adhesives to form an ‘I’ shape.The web of I joist can be cut open to accommodate wires and pipes. A common I-beam web will have 40mm pre-punched holes. The specific position and maximum size of the holes can be calculated according to the drawings and corresponding tables, as shown in Figure 2, and the strength of the I-beam will not be affected by the pipe cutting holes.

Low cost, high stiffness, light weight;

Exchangeable, achieve E0 environmental protection standard;

High degree of standardization system production components, reusable good.

Customized in China H20 timber beam For Wall Formwork System spruce formwork beam

H20 beam is an important part of the international common building formwork system. It is of light weight, high strength, good straightness, not easy to deformation, water and acid and alkali resistance on the surface. It can be used year-round and has low cost amortization costs. Can be used with domestic and foreign professional template system products.JIKEWOOD H20 Beam mainly use Pine wood .

Hollow Plastic Formwork board New Type Recycled Construction Material

Hollow Plastic Formwork (Shuttering) is though to conventional PP materials were modified by polymer additives, which improves the hardness of the template while ensuring its toughness. According to our experience and test report, our hollow plastic shuttering can be recycled up-to 50 times, the strength can reach to 3200MPa, the deformation rate is within 2mm and the diagonal line is within 0.5mm, which better meets the construction needs.It is a new type recycled construction build material.

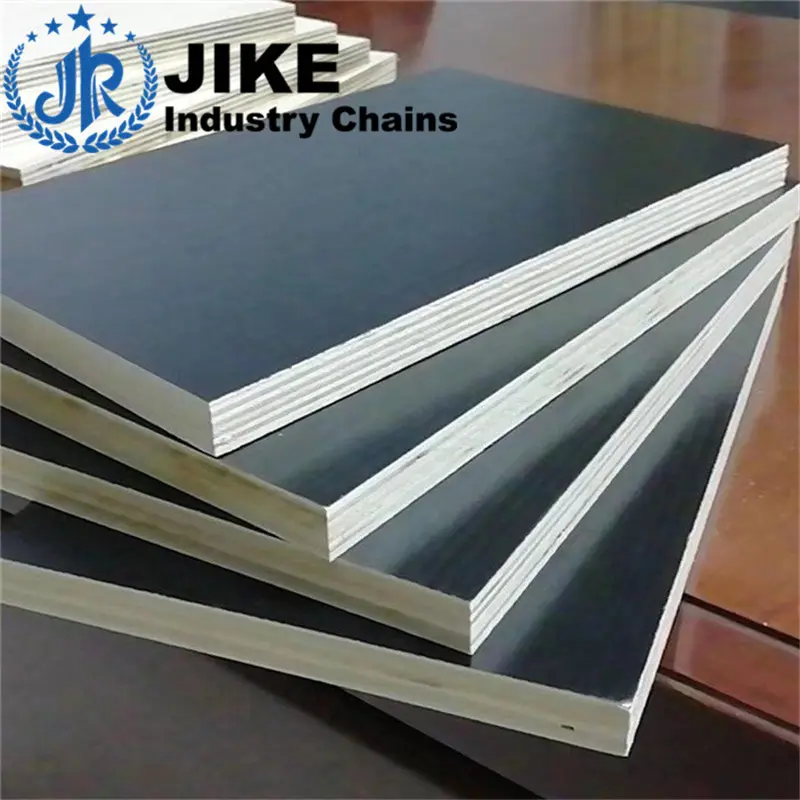

Black brown film faced plywood

Film faced plywood is the high-quality wood-based plywood covered with a layer of film-covered paper, and the film-covered paper and the wood-based panel are thermally pressed to form a building-covered template;

The surface of the film-covered board is smooth, bright, waterproof, fireproof, It has excellent durability (weather resistance, corrosion resistance, chemical resistance) and anti-fouling ability. The use of film-coated board construction makes the cement mold surface smoother, which can better remove the mold and avoid secondary ash. Improve work efficiency and save manpower and materials.