The Complete Guide to Black Walnut Plywood

Known as one of the most beautiful woods in the world, black walnut plywood is famous for its strength and appearance. But with various different options, how do you know which one is perfect for you? Don’t worry, you have come to the right place. Based on years of experience in the wood industry, this article will serve as a complete guide to black walnut plywood.

What is Black Walnut Plywood?

Black walnut plywood, also known by some as black hickory or juglans nigra, is a favorite among woodworkers for its versat

ility and ease of work. It features beautiful, even grains and a rich dark brown color, often with minimal flaws. This gives the plywood a sophisticated, elegant, and durable look, making it perfect for high - end furniture, cabinetry, and other applications where both aesthetics and strength are required.

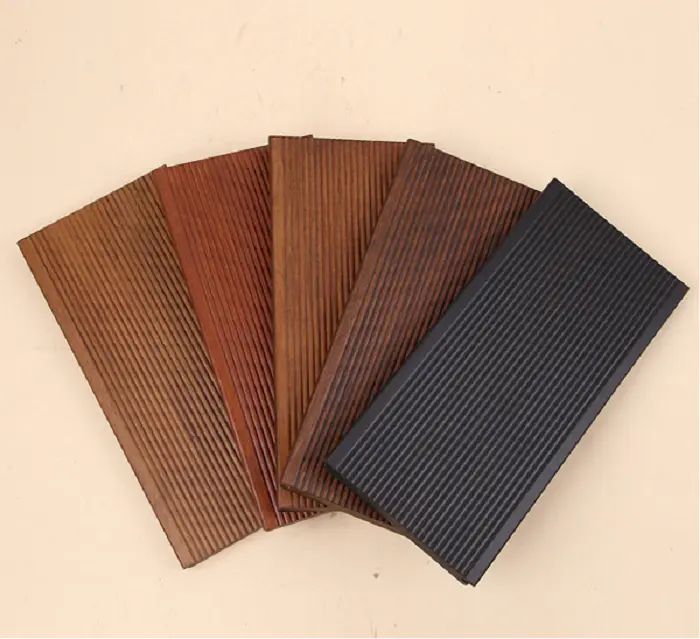

Different Core Types in Black Walnut Plywood

Black walnut plywood typically has a black walnut veneer on both the front

and back, but it comes with different core types, each having specific qualities:

1.Veneer Core: Made from stacking thin layers of wood veneer in alternate positions, with the grains forming a zig - zag pattern. Glue is applied between each layer. This core type is strong, durable, and lightweight yet sturdy. It provides a suitable base for various projects and is appropriate for heavy - duty usage in furniture and cabinetry.

1.MDF Core: Medium Density Fiberboard (MDF) core is made by bonding wood fibers and resin together using heat and pressure. MDF core black walnut plywood has a flat and smooth surface, making it suitable for applications where a flawless surface is essential, such as in doors, furniture, wall panels, or cabinets. It is more durable than veneer core but less effective at holding screws.

1.Particle Board Core: Cheaper than veneer and MDF cores, the particle board core is created by mixing wood chips and resin and pressing them into a solid panel. It has a smooth surface but is not as strong as other cores. It is suitable for moderate - usage furniture and fixtures and may lack water or weather resistance.

1.Lumber Core: Extremely strong and durable, the lumber core black walnut plywood offers the strength of real wood and the stability of plywood. Its solid core is made of strips of lumber. It can effectively hold screws and has a high resistance to warping, making it ideal for high - stress applications. However, it is heavier and more expensive than other core types.

1.Combination Core: As the name implies, this core combines multiple materials like veneer core, lumber core, MDF, and particleboard. It aims to improve the consistency and smoothness of the core. It is strong, lightweight, has a smooth surface, and can be used to create high - quality furniture. It also has the advantage of being paintable.

1.Plywood Core: Made with thin layers of one type of wood veneer, with glue applied between each layer. It is strong, can hold screws and bolts, and is resistant to warping. The use of one type of wood veneer ensures uniformity, making it suitable for different projects.

1.Hardwood Core: Made from sheets of hardwood, commonly birch and maple. The hardwood core is durable and provides more strength to the structure. It is more expensive due to its stability and excellent withstand capacity, making it perfect for heavy - duty, high - end furniture.

Applications of Black Walnut Plywood

Black walnut plywood's attractive appearance and robust properties make it a versatile material used in many sectors:

1.Furniture Making: It is an excellent choice for creating statement furniture pieces. Whether it's a luxurious dining table, a stylish bookshelf, or an elegant dresser, black walnut plywood can add a touch of sophistication.

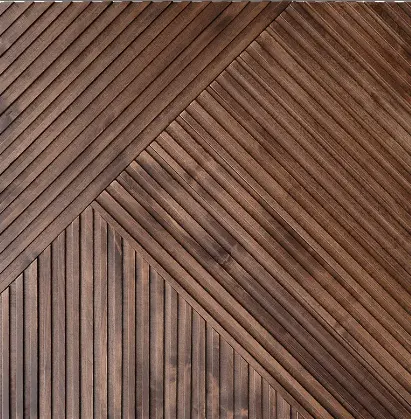

1.Interior Design: Used for interior wall paneling, it can transform a room, creating a warm and inviting atmosphere. It can also be used in ceiling designs to make a bold statement.

1.Cabinetry: Ideal for high - end kitchen cabinets, bathroom vanities, and storage cabinets. Its durability ensures that the cabinets will last for years.

1.Custom Doors: Black walnut plywood doors can be both functional and decorative, adding value to any property.

1.Luxury Flooring: Creates a high - end look for floors, and its strength can withstand heavy foot traffic.

1.Boat Building: Due to its resistance to decay and good strength - to - weight ratio, it can be used in boat construction, especially in interior components.

1.Musical Instruments: The unique acoustic properties of black walnut make it suitable for crafting musical instruments like guitars and pianos, where both sound quality and aesthetics matter.

1.Decorative Elements: Used for creating decorative accents such as wall art, picture frames, and decorative moldings.

Advantages of Using Black Walnut Plywood

1.Aesthetics: Its rich dark brown color and beautiful grain patterns add a touch of elegance and luxury to any project.

1.Durability: It is a strong and long - lasting material, suitable for applications that require resistance to wear and tear.

1.Versatility: Can be used in a wide range of applications, from furniture to boat building.

1.Workability: Works well with both machine and hand tools, allowing for easy shaping, carving, and drilling.

1.Cost - Effective: Compared to solid black walnut wood, plywood is more cost - effective while still maintaining a high - quality look.

1.Lightweight: Some core types, like veneer core, make the plywood lightweight, which is beneficial for handling and installation.

1.Easy to Maintain: With proper care, it can retain its appearance for a long time. Regular cleaning and protection from moisture are usually sufficient.

1.Resistant to Pests and Decay: Black walnut has natural properties that make it resistant to pests and decay, increasing its lifespan.

1.Customizability: Can be stained, painted, or finished in various ways to achieve the desired look.

1.Easily Accessible: Widely available from lumberyards and online suppliers.

Disadvantages of Using Black Walnut Plywood

1.Grading: The quality of black walnut plywood can vary significantly depending on the grade. Lower - grade plywood may have more knots, blemishes, or inconsistent grain patterns.

1.Moisture Sensitivity: Although it has some resistance to decay, it can still be affected by excessive moisture, which may cause warping or delamination.

1.Cost: While more cost - effective than solid black walnut, it can still be relatively expensive compared to some other types of plywood, especially higher - grade or specialty - core options.

Grades of Black Walnut Plywood

1.Grade A: Usually has the fewest imperfections, with a smooth surface and consistent grain pattern. It is ideal for high - end applications where appearance is crucial.

1.Grade B: Has a good surface but may have some minor blemishes or less - consistent grain. Still suitable for many furniture and interior design projects.

1.Grade C: May have more knots, larger blemishes, and a less uniform grain. It is often used for applications where appearance is not the primary concern, such as in some industrial or utility - based projects.

1.Grade D: The lowest grade, with significant imperfections. It is mainly used for applications where the plywood will be covered or where cost is the main consideration.

1.Custom Grades: Some suppliers may offer custom - graded plywood based on specific project requirements.

How to Choose the Right Black Walnut Plywood

1.Grade: Select a grade based on the appearance requirements of your project. If it's a visible, high - end piece, Grade A or B may be suitable. For less visible or more utilitarian projects, lower grades could be considered.

1.Size: Ensure the Plywood Sheets are of the appropriate size for your project. Standard sizes are available, but custom - sized sheets can also be ordered in some cases.

1.Thickness: Choose the thickness based on the application. Thicker plywood is generally stronger and more suitable for load - bearing applications, while thinner plywood may be used for decorative or less - demanding projects.

1.Appearance: Consider the grain pattern, color consistency, and overall aesthetic appeal. If you want a specific look, such as a particular grain direction or color tone, make sure to select the plywood accordingly.

1.Core Construction: As mentioned earlier, different core types have different properties. Choose a core type based on the strength, stability, and other requirements of your project.

1.Durability and Resistance: If your project will be exposed to moisture, heavy use, or other challenging conditions, select plywood with the appropriate durability and resistance properties.

1.Surface Preparation: Some plywood may come pre - finished, while others may require sanding, staining, or painting. Consider the surface preparation needed for your project.

1.Cost: Set a budget and compare the prices of different grades and types of black walnut plywood. Keep in mind that the cheapest option may not always be the best in terms of quality and performance.

1.Hot Press and Gluing Options: The quality of the hot - pressing and gluing process can affect the integrity of the plywood. Look for plywood that has been well - manufactured using high - quality glues.

1.Certificate: Some projects may require plywood with specific certifications, such as those related to environmental friendliness or safety standards. Make sure the plywood you choose meets the necessary certifications.

How to Handle Black Walnut Plywood

1.Transport: Handle the plywood carefully during transport to avoid damage. Protect it from scratches, dents, and moisture.

1.Preparation before Use: Inspect the plywood for any defects or damage before starting your project. If necessary, sand the surface to make it smooth.

1.Inspect: Thoroughly check each sheet for knots, splits, or other imperfections. Remove any damaged sheets from the stack.

1.Acclimate the Plywood: Allow the plywood to acclimate to the working environment for a few days before starting the project. This helps to reduce the risk of warping or cracking due to changes in temperature and humidity.

1.Cutting: Use sharp saw blades and appropriate cutting techniques to ensure clean cuts. Follow safety guidelines when using power tools.

1.Finishing: Apply the desired finish, such as stain, paint, or varnish, following the manufacturer's instructions. This will protect the plywood and enhance its appearance.

1.Installation: Install the plywood according to the project plan, using appropriate fasteners and adhesives. Make sure the installation is secure and level.

1.Maintenance and Care

1.Avoid Direct Sunlight: Prolonged exposure to direct sunlight can cause the color of the plywood to fade. Use curtains or blinds to protect it.

1.Protecting from Moisture: Keep the plywood away from sources of moisture, such as leaks or high - humidity areas. If it gets wet, dry it immediately to prevent warping or mold growth.

1.Regular Cleaning: Clean the plywood regularly with a soft, damp cloth. Avoid using harsh chemicals that may damage the finish.

Conclusion

Black walnut plywood is a versatile and attractive material that offers a wide range of applications in the woodworking and construction industries. By understanding its characteristics, core types, applications, advantages, and disadvantages, as well as how to choose and handle it properly, you can make the most of this beautiful wood product in your projects. Whether you are a professional woodworker or a DIY enthusiast, black walnut plywood can add a touch of luxury and durability to your creations.

FAQs

1.What is black walnut plywood?

Black walnut plywood is made by bonding layers of wood together, with a black walnut veneer on the surface. It is known for its strength, beauty, and versatility.

1.What are the different core types of black walnut plywood?

The core types include veneer core, MDF core, particle board core, lumber core, combination core, plywood core, and hardwood core, each with its own unique properties.

1.What are the applications of black walnut plywood?

It can be used in furniture making, interior design, cabinetry, custom doors, luxury flooring, boat building, musical instruments, and decorative elements.

1.What are the advantages of using black walnut plywood?

Advantages include aesthetics, durability, versatility, workability, cost - effectiveness, lightweight (depending on core type), easy maintenance, resistance to pests and decay, customizability, and easy accessibility.

1.What are the disadvantages of using black walnut plywood?

Disadvantages include grading variations, moisture sensitivity, and relatively high cost compared to some other plywood types.