Pine LVL Beam: An In - Depth Look

In the world of construction and woodworking, Pine LVL (Laminated Veneer Lumber) beam has emerged as a popular and reliable structural element. This engineered wood product offers a host of advantages over traditional solid wood beams and other construction materials.

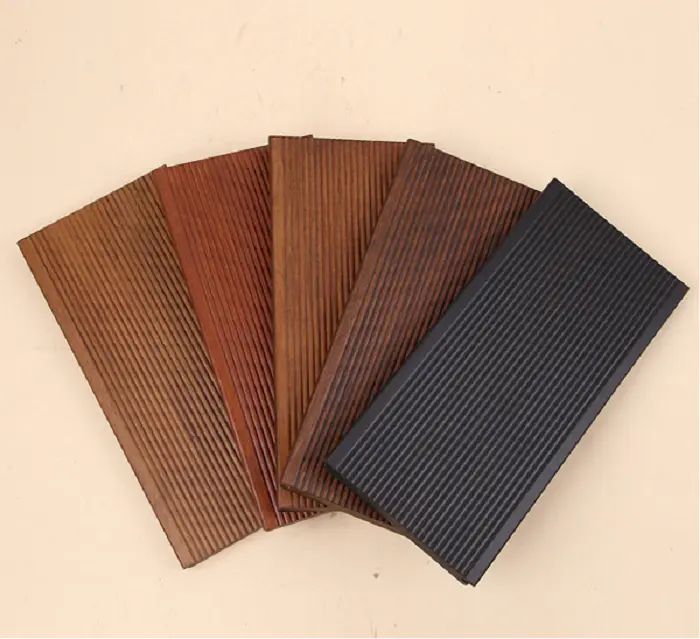

Manufacturing Process

Pine LVL beams are manufactured through a meticulous process. First, thin veneers of pine wood are carefully peeled from logs. These veneers are then dried to a specific moisture content to ensure stability. After drying, the veneers are coated with a high - quality adhesive. The coated veneers are stacked on top of each other in a way that the grain direction of adjacent layers is parallel. This parallel orientation of the grain significantly enhances the strength and stiffness of the final product. The stacked veneers are then pressed together under high pressure and heat. This pressing process not only ensures a strong bond between the veneers but also gives the beam its uniform shape and density.

Physical and Mechanical Properties

Strength

Pine LVL beams are known for their impressive strength. They can withstand heavy loads, making them suitable for use in a variety of construction applications. Their strength - to - weight ratio is quite favorable, which means they can support substantial loads while remaining relatively lightweight compared to some other materials. For example, in a multi - story building, Pine LVL beams can be used to support the floors and ceilings, providing a reliable and sturdy structure.

Stiffness

In addition to strength, Pine LVL beams offer high stiffness. Stiffness is crucial as it helps prevent excessive deflection under load. In a long - span application, such as a large - scale warehouse or a gymnasium, the stiffness of Pine LVL beams ensures that the structure remains stable and does not sag or bend significantly over time.

Durability

The manufacturing process of Pine LVL beams contributes to their durability. The adhesive used between the veneers protects the wood from moisture penetration to some extent. Additionally, pine wood itself can be treated with preservatives during the manufacturing process to further enhance its resistance to decay, insects, and fungi. This makes Pine LVL beams a long - lasting option for both indoor and outdoor construction projects.

Advantages over Solid Wood

Consistency

One of the major advantages of Pine LVL beams over solid wood is their consistency. Solid wood can have natural defects such as knots, splits, and variations in grain quality. These defects can weaken the structural integrity of the wood. Pine LVL beams, on the other hand, are made from multiple veneers, which are carefully selected and processed. This results in a more uniform product with fewer defects, providing a more reliable and consistent performance.

Size Flexibility

Solid wood is limited in size by the dimensions of the tree from which it is cut. Pine LVL beams can be manufactured in much larger sizes and longer lengths. This size flexibility makes them ideal for projects that require large - span structures. For instance, in the construction of a large - scale commercial building with wide open spaces, Pine LVL beams can be fabricated to the exact size needed to support the roof or upper floors.

Applications

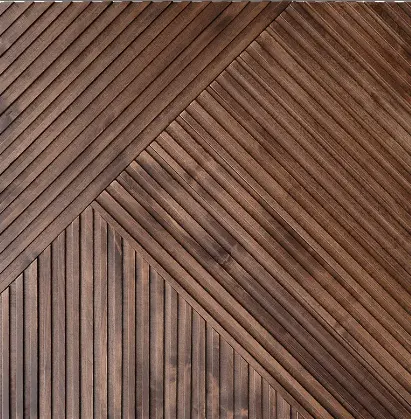

Residential Construction

In residential construction, Pine LVL beams are commonly used in floor and roof framing. They can support the weight of upper floors and the roof, providing a stable and safe structure. They are also used in the construction of porches, decks, and balconies, where their strength and durability are highly valued.

Commercial Construction

In commercial buildings, Pine LVL beams find extensive use in large - scale projects such as warehouses, factories, and shopping malls. Their ability to span long distances without intermediate supports makes them suitable for creating open - plan spaces. They are also used in the construction of office buildings, where they can be incorporated into the structural framework to support the weight of multiple floors.

Industrial Applications

In industrial settings, Pine LVL beams can be used in the construction of industrial sheds, storage facilities, and even in some cases, in the manufacturing of machinery components that require strong and reliable wooden structures.

In conclusion, Pine LVL beam is a versatile and high - performance engineered wood product. Its unique manufacturing process, excellent physical and mechanical properties, advantages over solid wood, and wide range of applications make it an integral part of modern construction and woodworking industries.