Introduction to CDX Pine Plywood

CDX pine plywood is a type of plywood made from multip

le lyers (plies) of thin wood veneers. The name "CDX" comes from its quality grade. The "C" and "D" refer to the grades of the face and back veneers respectively. The "C" grade indicates that the surface quality does not have to be perfect, which is suitable for applications where appearance is not the primary concern, such as structural uses. The "D" grade for the back veneer is also acceptable for non - visible parts in construction. The core layers are typically made of pine wood, which is known for its strength and workability. Pine is a softwood that is abundant in many regions, making it a cost - effective choice for plywood production.

1. Manufacturing Process

The manufacturing of Cdx Pine Plywood involves several steps. First, logs of pine trees are debarked and then sliced into thin veneers. These veneers are carefully inspected for any defects. Next, the veneers are arranged in alternating layers with their grain directions perpendicular to each other. This cross - laminating technique significantly enhances the strength and stability of the plywood. After the veneers are stacked, a waterproof adhesive is applied between each layer. The stack is then subjected to heat and pressure in a press. The heat activates the adhesive, and the pressure ensures a strong bond between the layers, resulting in a solid and durable plywood sheet. This process makes CDX pine plywood resistant to warping and splitting, even when exposed to changing environmental conditions.

2. Advantages

2.1 Strength and Stability

Thanks to its multi - layer construction and the use of high - quality pine, CDX pine plywood offers excellent strength and stability. It can bear heavy loads, making it suitable for applications where structural integrity is essential. For example, in a building's subfloor, the CDX pine plywood can support the weight of furniture, appliances, and people walking on it without significant deflection or damage. In roof construction, it provides a solid base for roofing materials such as shingles or metal sheets.

2.2 Moisture Resistance

Pine wood itself has some natural moisture - resistant properties, and when combined with the waterproof adhesive used in the manufacturing process, CDX pine plywood becomes even more resistant to moisture. This makes it suitable for both indoor and outdoor applications. In outdoor projects like sheds, decks, or fences, the plywood can withstand exposure to rain, humidity, and temperature changes without rotting or delaminating easily. In indoor applications such as basements or bathrooms, where there is a higher humidity level, CDX pine plywood can maintain its integrity.

2.3 Cost - Effectiveness

Compared to some other building materials, CDX pine plywood is relatively affordable. The abundance of pine wood and the efficient manufacturing process contribute to its cost - effectiveness. It offers a good balance between price and performance, making it a popular choice for many construction projects, especially those with budget constraints. For example, in small - scale home improvement projects like building a DIY storage shed or renovating a basement, CDX pine plywood can provide a cost - efficient solution without sacrificing quality.

2.4 Workability

CDX pine plywood is easy to work with. It can be easily cut, drilled, nailed, or screwed using standard woodworking tools. This workability allows construction workers and DIY enthusiasts to shape the plywood according to their project requirements. Whether it's cutting it into specific sizes for a flooring project or drilling holes for installing fixtures, the plywood responds well to these operations, providing flexibility in design and construction.

2.5 Environmental Friendliness

Pine is a renewable resource, and many plywood manufacturers source their pine wood from sustainably managed forests. CDX pine plywood production generally involves less energy - intensive processes compared to some synthetic building materials. Additionally, it does not contain harmful substances such as formaldehyde in large amounts, which is beneficial for indoor air quality. This makes it an environmentally friendly choice for both new construction and renovation projects.

3. Common Applications

3.1 Construction

- Subflooring: CDX pine plywood is widely used as a subfloor material. It provides a flat and sturdy base for various types of finished flooring, including hardwood, tile, or carpet. The strength of the plywood ensures that the finished floor remains level and free from squeaks or unevenness.

- Roofing: It serves as a roof decking material. The plywood is installed over the roof rafters and provides a solid surface for attaching roofing materials. Its moisture resistance is crucial in protecting the underlying structure from water damage caused by rain or snow.

- Wall Sheathing: In building walls, CDX pine plywood is used as wall sheathing. It helps to strengthen the wall structure and provides a surface for attaching siding, insulation, or interior finishes.

3.2 Industrial Use

- Pallets: CDX pine plywood is often used to make pallets for shipping and storage. The strength and durability of the plywood allow it to carry heavy loads during transportation and storage in warehouses. Pallets made from CDX pine plywood are also relatively lightweight compared to some other materials, which helps to reduce shipping costs.

- Formwork: In the construction of concrete structures, CDX pine plywood is used as formwork. It is shaped and assembled to create the molds into which concrete is poured. The smooth surface of the plywood allows for easy removal of the formwork after the concrete has hardened, resulting in a smooth concrete finish.

3.3 DIY and Home Improvement

- Furniture Making: For those interested in DIY furniture projects, CDX pine plywood can be used to make simple yet sturdy furniture pieces such as bookshelves, cabinets, or workbenches. The cost - effectiveness and workability of the plywood make it accessible for home - based projects.

- Home Renovation: In home renovation projects, CDX pine plywood can be used for various purposes, such as creating partitions, building storage spaces, or covering damaged walls or floors temporarily.

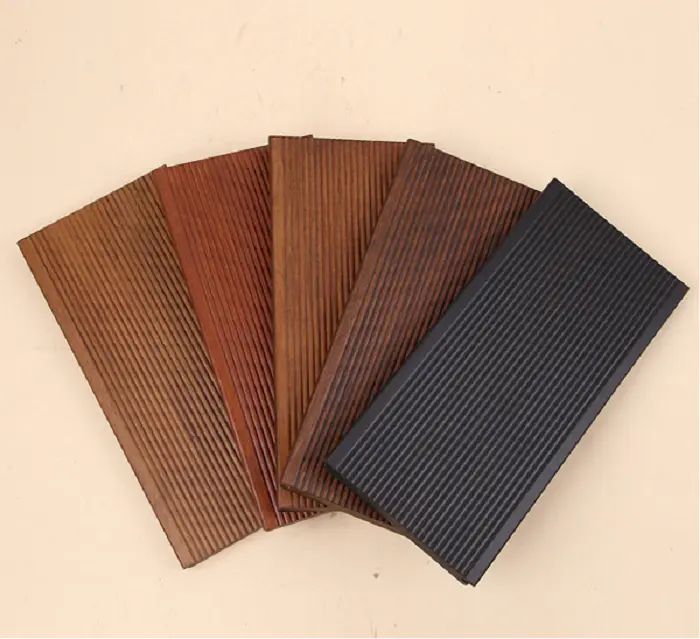

4. Sizes and Thicknesses

CDX pine plywood is available in a variety of sizes and thicknesses to meet different project requirements. Common sheet sizes include 4 feet by 8 feet, which is a standard size in the construction industry. However, other sizes such as 5 feet by 5 feet or 4 feet by 10 feet may also be available. Thicknesses typically range from 1/4 inch to 1 inch. Thinner plywood, such as 1/4 - inch or 3/8 - inch, may be used for applications where weight is a concern or for decorative purposes. Thicker plywood, like 3/4 - inch or 1 - inch, is more suitable for structural applications that require greater strength and load - bearing capacity.

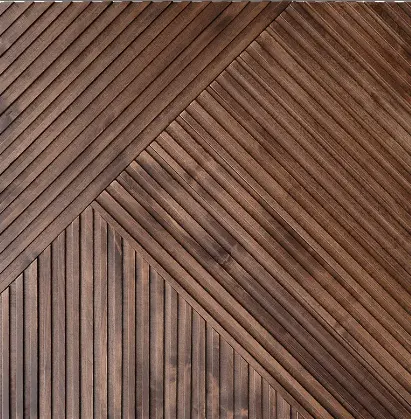

5. Surface Treatment

Before using CDX pine plywood in certain applications, surface treatment may be necessary. Surface treatment can enhance the plywood's properties such as waterproofing, durability, and appearance. One common surface treatment is applying a coat of paint or sealant. A waterproof paint or sealant can further improve the plywood's resistance to moisture, especially in outdoor applications. Another treatment option is laminating the surface with a thin layer of decorative material, such as a veneer of a more expensive wood species, to improve its aesthetic appeal for furniture or interior design projects.