Formwork engineering: plywood formwork

Plywood formwork, as an indispensable material in the modern construction industry, has a pivotal position in the formwork market due to its unique structure and excellent performance. This paper will conduct a comprehensive and in-depth discussion on the composition, manufacturing process, performance characteristics and application prospects of plywood formwork.

First, the composition of the plywood formwork

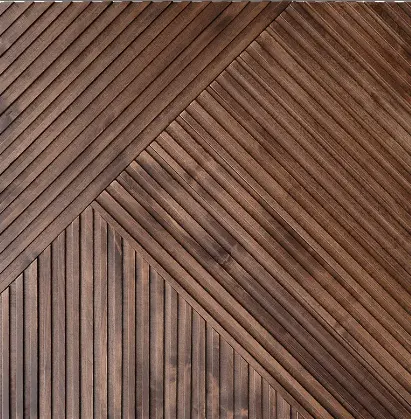

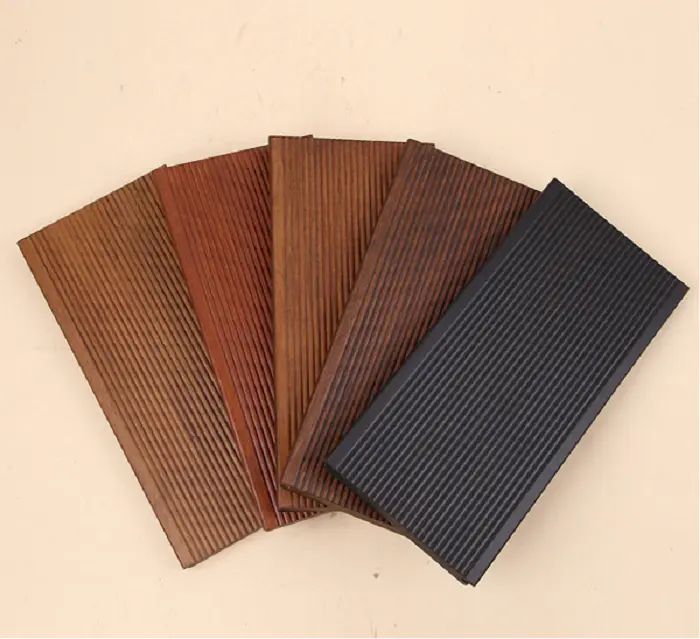

Plywood formwork, as the name suggests, is a plate-like material made from thin formwork of multi-layer wood or bamboo material bonded together by industrial glue such as phenolic glue, triamine glue, or white glue. The fibers of these thin formwork are perpendicular to each other, and this structure allows the plywood formwork to maintain strength while also having good resistance to deformation. The thickness of the common plywood formwork is mostly 12mm, 15mm, 18mm, and the board surface size is mainly 1830mmX915mm and 1220mmX2440mm, and the design of these specifications fully takes into account the versatility and construction efficiency of the building formwork.

Second, the production process of plywood formwork

The manufacturing process of plywood formwork includes steps such as raw material preparation, veneer rotary cutting, drying, gluing, blank assembly, hot pressing, sawing and inspection. First of all, high-quality wood or bamboo is selected as raw material, and it is cut into thin templates by a rotary cutting machine. The thin stencil is then dried to reduce its moisture content and improve the quality of the glue. Next, the surface of the thin stencil is evenly coated with industrial glue and the blanks are assembled according to the principle that the fibers are perpendicular to each other. After the blank is assembled, it is fed to the hot press for hot pressing, so that the layers of the template are firmly bonded. Finally, the formed plywood formwork is sawed and inspected to ensure that its dimensions are accurate and the quality is reliable.

Third, the performance characteristics of plywood formwork

Plywood formwork has many excellent performance characteristics. First of all, it has a large plate width and light weight, which is easy to handle and install. Secondly, the board surface is smooth and easy to cut, which can meet various complex construction needs. In addition, the plywood formwork is also easy to bend and form, which can adapt to the construction of various curved structures. Most importantly, the plywood formwork has high strength and stability, and can withstand large pressures and impacts. These performance characteristics make plywood formwork widely used in construction projects.

Fourth, the application prospect of plywood formwork

With the rapid development of the construction industry and the continuous progress of technology, the application prospect of plywood formwork is getting broader and broader. On the one hand, with the increase of complex buildings such as high-rise buildings and long-span structures, the requirements for formwork materials are getting higher and higher. With its excellent performance characteristics, plywood formwork can meet the formwork material needs of these complex buildings. On the other hand, with the improvement of environmental awareness and the requirements of sustainable development, plywood formwork, as a green building material, has received more and more attention and favor. Its raw materials are widely sourced, recyclable and reusable, and meet the requirements of environmental protection and sustainable development.