Comparison of Plywood and Bamboo Plywood in Furniture Production

1. Material Composition and Manufacturing Process

1.1 Plywood

Plywood is typically made from thin layers of wood veneer. These veneers are cut from logs, usually of softwood species like pine, or hardwoods such as birch and oak. The manufacturing process involves peeling the logs into thin sheets, which are then dried to reduce moisture content. Subsequently, the veneer sheets are coated with adhesives and stacked in a way that the grain direction of adjacent layers is perpendicular to each other. This cross - grain construction enhances the strength and stability of the plywood. The stacked layers are then pressed together under high pressure and heat to bond them firmly, forming the plywood panel.

1.2 Bamboo Plywood

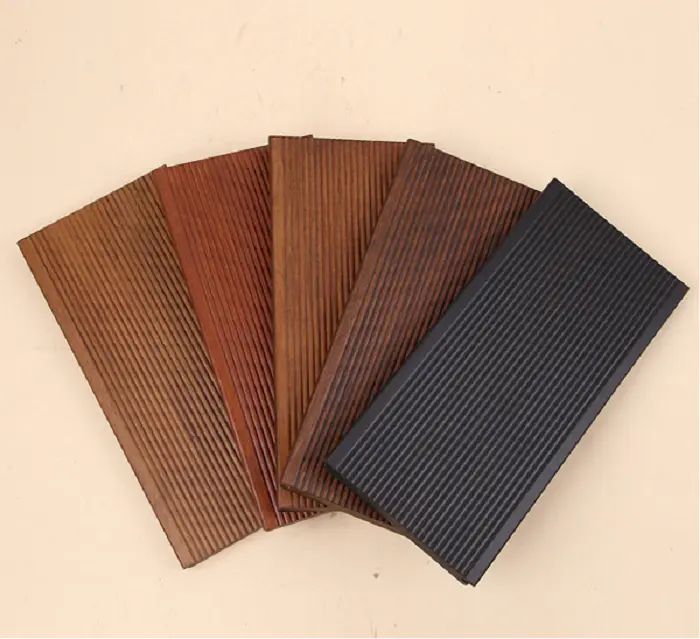

Bamboo plywood, on the other hand, is manufactured from bamboo strips. Bamboo, a fast - growing grass, is harvested and processed into thin strips. These strips are also dried to remove moisture. After drying, the bamboo strips are glued together using adhesives. Similar to plywood, the bamboo strips in bamboo plywood are often arranged in a pattern to improve strength. The bamboo strips can be oriented in various ways, such as parallel or in a cross - laminated structure. The glued - up bamboo layers are then pressed to create a solid and stable panel.

2. Physical and Mechanical Properties

2.1 Strength and Durability

**

2.1.1 Plywood

Plywood has good strength properties. The cross - laminated structure provides it with decent resistance to bending and impact. However, the strength can vary depending on the type of wood used for the veneers. For example, Plywood Made From hardwood veneers generally has higher strength compared to that made from softwood veneers. In terms of durability, plywood can be quite durable if properly protected. But it is susceptible to damage from moisture, which can cause delamination (the separation of the veneer layers) over time.

2.1.2 Bamboo Plywood

Bamboo plywood is known for its high strength - to - weight ratio. Bamboo itself has natural strength, and when processed into plywood, it retains a significant amount of that strength. In fact, some studies suggest that bamboo plywood can be even stronger than certain types of hardWood Plywood. It also has good durability. Bamboo's natural density and the manufacturing process make it resistant to wear and tear. Additionally, bamboo plywood is less likely to warp or crack compared to plywood in normal indoor conditions.

2.2 Moisture Resistance

2.2.1 Plywood

Plywood has relatively poor moisture resistance. Wood is a hygroscopic material, meaning it absorbs and releases moisture depending on the ambient humidity. When plywood is exposed to high humidity or water, the wood veneers can swell, which may lead to warping, cupping, or delamination. Although some plywood may be treated with water - resistant adhesives or coatings, it still cannot match the moisture - resistant properties of bamboo plywood in extreme conditions.

2.2.2 Bamboo Plywood

Bamboo has a natural waxy coating that gives it better moisture - resistant properties compared to wood. Bamboo plywood, therefore, has a higher resistance to moisture absorption. It can withstand higher humidity levels without significant swelling or warping. This makes it an ideal choice for furniture that may be exposed to slightly humid environments, such as in bathrooms or kitchens (with proper finishing). However, it should be noted that continuous and direct exposure to water can still cause damage to bamboo plywood over time.

2.3 Hardness

2.3.1 Plywood

The hardness of plywood depends on the type of wood veneers used. Hardwood - based plywood is generally harder than softwood - based plywood. However, compared to bamboo plywood, plywood may be relatively softer. Softer plywood may be more prone to scratches and dents when in use, especially in high - traffic areas or when heavy objects are placed on furniture made from it.

2.3.2 Bamboo Plywood

Bamboo plywood is relatively hard. Bamboo's natural fiber structure contributes to its hardness, making it more resistant to scratches and dents. This property makes bamboo - plywood - made furniture suitable for areas where the furniture may be subject to regular wear and tear, such as in a living room with children or pets.

3. Aesthetic Appeal

3.1 Plywood

Plywood offers a variety of aesthetic options. The natural grain patterns of the wood veneers can be quite attractive, especially when made from high - quality hardwoods like oak or cherry. It can be stained or painted to achieve different colors and finishes, allowing for a wide range of design possibilities. However, if the plywood is not of high quality, the joints between the veneer layers may be visible, which can detract from its overall aesthetic appeal.

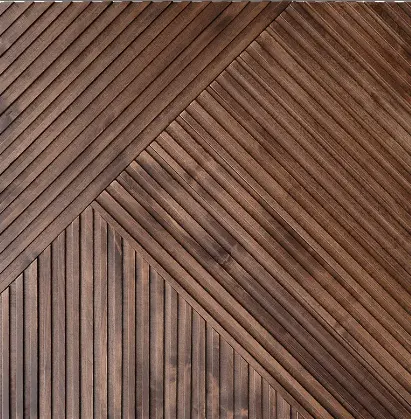

3.2 Bamboo Plywood

Bamboo plywood has a unique and natural aesthetic. The bamboo strips create a distinct pattern that gives furniture a warm, organic look. It has a light - colored, natural appearance that can bring a touch of the outdoors indoors. Bamboo plywood can also be stained or finished to change its color, but its natural color and texture are often preferred for a more eco - friendly and natural design aesthetic.

4. Environmental Impact

4.1 Plywood

The production of plywood requires the harvesting of trees. Although many plywood manufacturers source their wood from sustainably managed forests, the overall process still contributes to deforestation if not properly regulated. Additionally, the adhesives used in plywood production may contain harmful chemicals such as formaldehyde, which can be released into the indoor environment over time, posing a potential health risk.

4.2 Bamboo Plywood

Bamboo is a highly renewable resource. It grows much faster than trees, with some species of bamboo reaching maturity in as little as 3 - 5 years. This makes bamboo plywood a more environmentally friendly option in terms of raw material sourcing. Moreover, the adhesives used in bamboo plywood production can be low - VOC (volatile organic compound) or formaldehyde - free, reducing the environmental impact during the manufacturing process and also minimizing the risk of indoor air pollution.

5. Cost

5.1 Plywood

The cost of plywood can vary depending on the type of wood used, the quality of the veneers, and the thickness of the panel. Generally, softwood - based plywood is more affordable, while hardwood - based plywood, especially those made from rare or high - quality hardwoods, can be relatively expensive. In the mid - range, plywood is often a cost - effective option for furniture production, especially for large - scale manufacturing where cost control is crucial.

5.2 Bamboo Plywood

Bamboo plywood is typically more expensive than plywood. The cost is influenced by factors such as the quality of the bamboo, the manufacturing process, and the market demand. The relatively higher cost of bamboo plywood can be attributed to the specialized processing required for bamboo, as well as the fact that it is still considered a more niche product in the furniture market compared to plywood. However, its long - term durability and environmental benefits may offset the higher initial cost for some furniture manufacturers and consumers who value these aspects.

6. Conclusion

In conclusion, both plywood and bamboo plywood have their own sets of advantages and disadvantages in furniture production. Plywood is a well - established material with a wide range of aesthetic options and a relatively lower cost in some cases, but it has limitations in terms of moisture resistance and environmental impact. Bamboo plywood, on the other hand, offers superior strength, better moisture resistance, a unique aesthetic, and a more sustainable option, albeit at a higher cost.

Furniture manufacturers need to carefully consider their specific requirements, such as the intended use of the furniture, the desired aesthetic, budget constraints, and environmental concerns when choosing between plywood and bamboo plywood. By weighing these factors, they can select the material that best suits their production needs and creates high - quality, durable, and appealing furniture products.