Leave Your Message

-

Whatsapp

-

Whatsapp

Ply Board Wood has emerged as a vital material in the construction and furniture industries, thanks to its versatility and resilience. In recent years, the global ply board market has shown significant growth, with a projected increase from USD 83 billion in 2021 to approximately USD 120 billion by 2026, according to industry reports. This growth reflects a rising demand for sustainable construction materials and innovative design solutions that ply board wood offers, fulfilling the needs of both commercial and residential projects.

Understanding the characteristics and best practices associated with Ply Board Wood is essential for anyone involved in woodworking or construction. Not only is it an eco-friendly alternative, reusing and recycling wood fibers, but it also provides considerable cost savings without compromising quality. Furthermore, because of its layered structure, ply board wood offers superior strength and resistance to warping compared to solid wood, making it an excellent choice for various applications, from cabinetry to flooring. As we delve into the top ten things you need to know about Ply Board Wood, a comprehensive understanding will equip you to select the right materials for your next project efficiently.

Ply board wood, commonly referred to as plywood, is a versatile engineered wood product made from thin layers or "plies" of wood veneer that are glued together. This construction technique provides enhanced strength and durability, making it a popular choice in various construction and furniture applications. According to the Wood Products Council, the demand for plywood in the construction industry is on the rise, with a projected growth rate of 4.5% annually through 2025, driven largely by its sustainable sourcing and cost-effectiveness compared to solid wood.

There are several types of plywood, each designed to meet different project requirements. For example, exterior-grade plywood is treated to withstand moisture and is ideal for outdoor applications, while interior-grade plywood is primarily used for furniture and cabinetry. Additionally, specialty plywood like marine plywood is treated for water resistance, making it suitable for boats and other aquatic applications. As per industry insights from the American Plywood Association, the construction sector heavily utilizes structural plywood, which contributes significantly to the stability and longevity of structures.

Tips for selecting the right type of plywood include assessing the environment in which it will be used. For outdoor projects, choose exterior-grade plywood with a proper veneer type to prevent warping. When working on furniture, consider the aesthetic of the veneer finish while ensuring the board meets your strength and durability needs. Remember, investing time in selecting the correct plywood can enhance the quality and longevity of your projects.

Ply board, known for its versatility and strength, is a popular choice in construction and furniture design. One of its key properties is its incredible strength, which comes from layers of thin veneer bonded together. This laminated structure not only enhances its load-bearing capacity but also ensures that it resists warping and splitting, making it suitable for a wide range of applications. Whether you’re building cabinets, shelves, or even flooring, ply board provides reliable support, especially when compared to other types of wood products.

Another significant attribute of ply board is its durability. Resistant to moisture and wear, it maintains its integrity even in challenging conditions, making it an excellent option for environments that may experience fluctuations in humidity or temperature. This durability translates into a longer lifespan for projects, reducing the need for frequent replacements. Additionally, the lightweight nature of ply board makes it easy to handle and install, which is particularly beneficial for DIY enthusiasts and professional builders alike. The combination of strength, durability, and manageable weight positions ply board as a fundamental material for both simple and complex woodworking projects.

Ply board, also known as plywood, has gained significant popularity in both construction and furniture making due to its versatility and strength. In construction, ply board serves as an essential material for framing, subflooring, and wall sheathing. Its layers of veneer are glued together in a cross-grain pattern, which enhances its durability and resistance to warping, making it ideal for structural applications. Moreover, its lightweight nature simplifies handling and reduces overall construction costs, allowing builders to efficiently complete projects without compromising on strength.

In the realm of furniture making, ply board’s adaptability makes it a favored choice for craftsmen and designers alike. It can be easily shaped and finished, allowing for creative designs that cater to modern aesthetics. From cabinets to tables and chairs, ply board can be employed in an array of furniture items. Its smooth surface is perfect for painting or veneering, giving furniture a polished look while retaining the structural integrity. Additionally, the sustainability aspect of using ply board, often made from fast-growing trees, appeals to environmentally conscious consumers, making it a responsible choice for both builders and furniture makers.

Plywood, or ply board, is favored in construction and furniture-making for its strength and versatility. However, the environmental impact of its production raises concerns worth discussing. The primary sustainability issue stems from the sourcing of wood; if timber comes from unsustainable logging practices, it can contribute to deforestation, loss of biodiversity, and increased carbon emissions. Therefore, it's crucial to choose plywood manufactured from responsibly sourced materials that comply with sustainable forestry practices.

When considering ply board for your projects, always check for certifications such as the Forest Stewardship Council (FSC) label. This ensures the wood has been harvested sustainably. Additionally, opting for products made from recycled wood can further reduce environmental impact. To minimize waste, think about how you can repurpose off-cuts and scraps from your projects. Not only does this practice enhance sustainability, but it also nurtures creativity in your woodworking endeavors.

To protect the environment while using ply board, consider selecting materials that are less toxic. Some plywood options contain fewer volatile organic compounds (VOCs), which can be harmful to both health and the planet. Using low-VOC adhesives and finishes will contribute to a healthier indoor environment and lessen the ecological footprint of your projects.

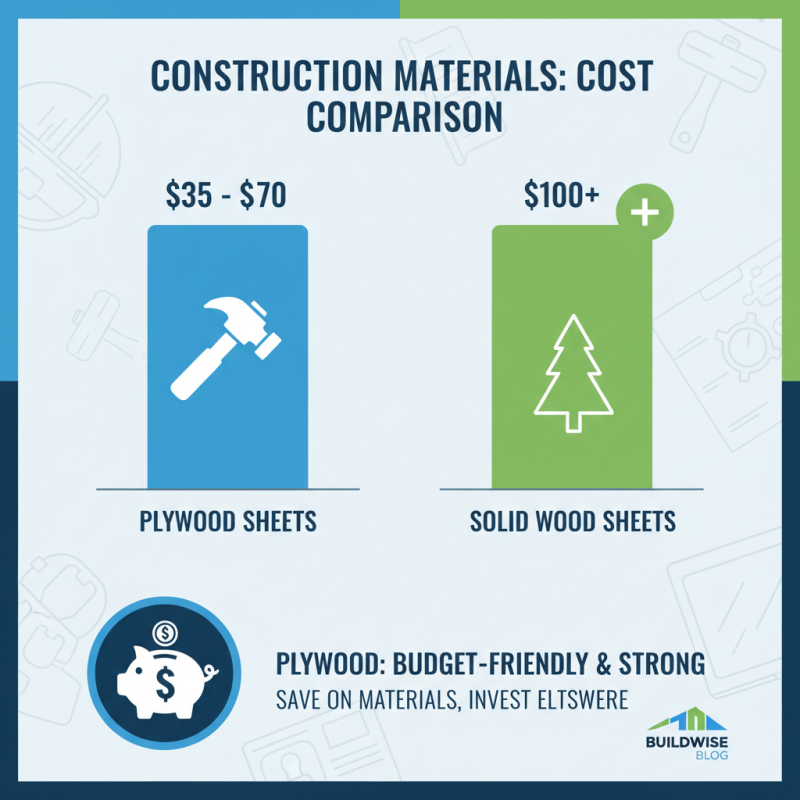

When considering materials for construction projects, cost is often a determining factor. Ply board, or plywood, is known for its versatility and strength, making it an attractive option for many builders. According to industry reports, the average cost for high-quality plywood ranges from $35 to $70 per sheet, which is competitive compared to solid wood, which can exceed $100 per sheet. This price efficiency allows builders to allocate budget towards other critical areas of their projects.

A critical aspect when comparing costs between ply board and other materials is the long-term savings associated with durability. Plywood is resistant to warping and cracking, providing longevity that can lower replacement costs over time. Studies have shown that projects utilizing ply board can reduce overall expenses by up to 15% compared to traditional solid wood construction, especially in regions prone to fluctuating humidity that can affect wood stability.

Tips: When selecting materials, consider not only initial costs but also potential maintenance expenses over the project's lifespan. Additionally, optimizing cutting patterns during fabrication can maximize the utilization of each sheet of plywood, reducing waste and ultimately contributing to cost savings. Always factor in local pricing variances, as transportation and availability can impact overall expenses significantly.