Leave Your Message

-

Whatsapp

-

Whatsapp

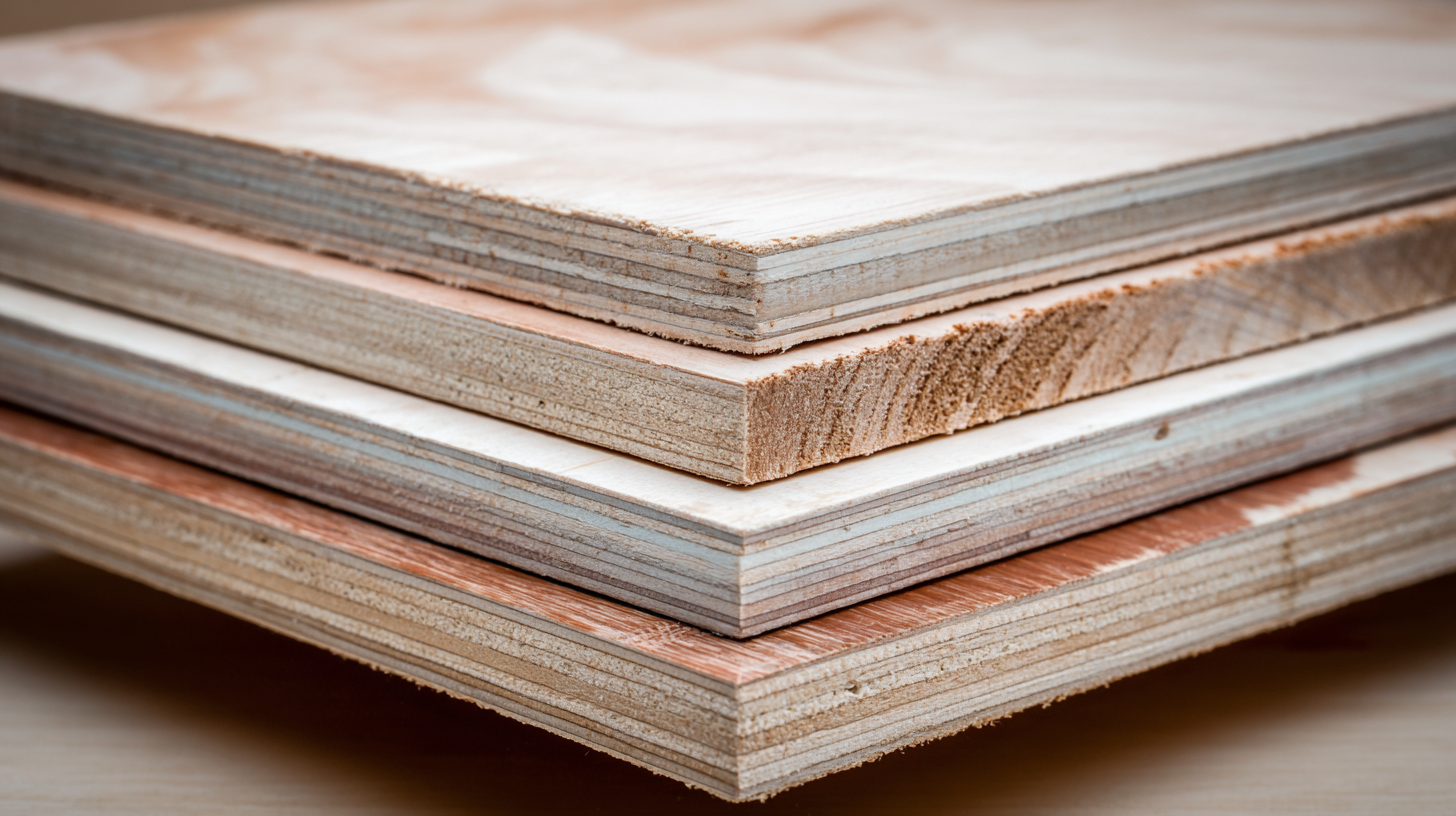

Film Faced Plywood has become an essential material in the construction and architectural industries due to its durability and water resistance, making it ideal for formwork applications. According to a recent report by TechNavio, the global film faced plywood market is projected to grow by USD 3.1 billion between 2020 and 2024, driven by the increasing demand for sustainable building materials and the rise of infrastructure projects worldwide. As contractors and builders in pursuit of quality materials navigate the myriad of options available, understanding the key factors that influence the selection of film faced plywood is crucial. In this blog, we will unveil seven secrets that can guide you in making informed choices for your projects, ensuring not only the structural integrity but also the long-term performance of your investments. Explore the fine craftsmanship inherent in "精工细造,中国制造,服务世界" as we delve into what sets the best film faced plywood apart from the rest.

When it comes to selecting film faced plywood for construction and furniture projects, understanding the various types available is crucial. Film faced plywood is typically categorized by the type of film applied to its surface, which can significantly influence its performance and applicability. For instance, phenolic film faced plywood is renowned for its moisture resistance and durability, boasting a lifespan that can exceed 15 years in outdoor applications. This makes it an ideal choice for construction use in climates prone to humidity, as highlighted by the Wood Products Council, which indicates that such products can reduce maintenance costs in the long run.

On the other hand, melamine film faced plywood offers a smoother surface finish ideal for aesthetic applications, including cabinetry and furniture. According to a report from the Plywood Manufacturers Association, melamine film faced options have seen a surge in demand, particularly in residential applications, due to their versatility and appealing appearance. Buyers must also consider the film thickness, as variations can impact the board's resilience to wear and tear, with thicker films providing greater protection and enhancing overall functionality in high-traffic conditions. Understanding these distinctions is essential for selecting the best film faced plywood to meet specific project requirements.

When selecting high-quality film faced plywood for your projects, several key features should guide your choice. First and foremost, consider the type of film used on the plywood. A higher-grade film, such as phenolic resin, offers superior water resistance and durability, making it ideal for projects exposed to moisture or harsh conditions. Additionally, the thickness of the plywood and the film layer can significantly impact the material's overall strength and lifespan. Ensure the film is adequately bonded to the plywood to prevent delamination during use.

Another essential aspect to evaluate is the surface finish of the plywood. A smooth, even surface not only enhances the aesthetic appeal of your project but also promotes better adhesion for any coatings or finishes applied later. Look for plywood with minimal imperfections and a uniform color to achieve the best results. Additionally, understanding the grading system can help you identify plywood that meets your specific requirements, whether for structural support or decorative use. By focusing on these features, you can choose the best film faced plywood that meets both your aesthetic and functional needs.

When selecting film faced plywood for your projects, understanding its applications can significantly enhance your results. Film faced plywood is predominantly used in construction due to its durability and resistance to water and chemicals. According to a recent industry report, this type of plywood can withstand extensive wear and tear, making it ideal for concrete formwork, scaffolding, and temporary structures.

Its non-porous surface ensures that it can be reused multiple times without significant degradation, thus optimizing both cost and efficiency in construction tasks.

In addition to construction, film faced plywood is also a solid choice for various furniture applications, especially in outdoor settings. The protective film helps guard against moisture, which is crucial for items exposed to the elements. Recent studies indicate that projects utilizing film faced plywood tend to have a longer lifespan when compared to those using untreated wood, with some applications showing an increase in durability by over 30%. This makes it a preferred material for architects and contractors looking to create structures that blend utility with sustainability.

In addition to construction, film faced plywood is also a solid choice for various furniture applications, especially in outdoor settings. The protective film helps guard against moisture, which is crucial for items exposed to the elements. Recent studies indicate that projects utilizing film faced plywood tend to have a longer lifespan when compared to those using untreated wood, with some applications showing an increase in durability by over 30%. This makes it a preferred material for architects and contractors looking to create structures that blend utility with sustainability.

Film faced plywood is a popular choice in construction and furniture making, prized for its durability and water resistance. To ensure longevity and maintain its aesthetic appeal, proper care and maintenance are essential. One of the key aspects of caring for film faced plywood is regular cleaning. After each use, it’s important to wipe the surface with a soft cloth and a mild detergent solution to remove any debris or sticky residues. Avoid abrasive cleaners or rough sponges that could scratch the film surface, which could compromise its protective properties.

Another crucial aspect of maintenance is the storage of film faced plywood. When not in use, it should be stored in a dry, well-ventilated area, away from direct sunlight to prevent warping or delamination. Stacking the plywood properly with spacers can help maintain airflow and reduce the risk of moisture buildup. Additionally, applying a protective sealant can enhance the plywood's lifespan, offering extra resistance against water and stains. With these simple yet effective maintenance tips, you can ensure that your film faced plywood retains its integrity and performance for years to come.

| Dimension | Importance | Care Tips | Lifespan |

|---|---|---|---|

| Thickness | Critical for load-bearing capacity | Avoid exposing edges | 5-10 years |

| Finish Quality | Affects appearance and durability | Regular cleaning and inspection | 4-8 years |

| Water Resistance | Essential for exterior use | Seal edges and surfaces | 6-12 years |

| Grain Pattern | Affects aesthetic appeal | Use appropriate protective coatings | 3-7 years |

| Density | Determines sturdiness | Avoid heavy impacts | 7-15 years |

| Finish Type | Impacts maintenance needs | Clean spills immediately | 4-10 years |

| Usage Environment | Crucial for lifespan | Store away from moisture | 5-12 years |

When selecting film faced plywood, one of the most critical factors to consider is the film thickness, which directly impacts the plywood's performance and longevity in your specific projects. Typically, film faced plywood comes in a range of thicknesses, with 120 grams per square meter (gsm) being the most common for general use, while higher thicknesses such as 240 gsm are preferred for more demanding applications. According to the Plywood Association, using a thicker film can significantly enhance the board's resistance to moisture and abrasion, extending its lifespan and maintaining its structural integrity under challenging conditions.

Furthermore, projects that involve concrete formwork often benefit from thicker films as they provide better release properties, allowing for a smoother finish and easier demolding. A study by the American Concrete Institute indicates that the right film thickness can reduce the amount of labor required for surface preparation, which translates into cost savings during construction. Therefore, when choosing film faced plywood, it’s essential to assess the specific needs of your project, as opting for the appropriate film thickness can dramatically affect both the project’s efficiency and final quality.