Leave Your Message

-

Whatsapp

-

Whatsapp

Osb Board Plywood is a remarkable building material. It combines the strength of plywood with unique properties of oriented strand board. This fusion creates a versatile option for numerous applications.

In construction, Osb Board Plywood is often favored for its durability. It's used for flooring, wall sheathing, and roof decking. The wood strands are arranged strategically. This method enhances structural integrity while allowing for efficient material use.

However, not all projects benefit equally from Osb Board Plywood. Some may find its moisture resistance lacking. This can lead to concerns in humid climates. It's essential to evaluate the project's needs before choosing this material. Awareness of these factors can lead to better decision-making in construction ventures.

OSB board plywood, or oriented strand board, is a popular engineered wood product. Its definition lies in its specific composition. OSB is made from strands of wood that are oriented in specific directions. These strands are then bonded together using adhesives and pressed to create large panels. This structure enhances its strength and durability compared to other wood products.

According to the North American OSB Manufacturers Association, OSB accounts for a significant portion of the structural panel market. In 2022, it represented nearly 45% of the total structural panel production. This reflects a growing preference for OSB in construction. The costs associated with OSB are often lower than plywood, making it an attractive option for builders. However, it is crucial to consider the environmental impact of its production. The sourcing of wood strands and the manufacturing process can have serious repercussions on forest ecosystems.

In terms of application, OSB board plywood is primarily used for sheathing and flooring in residential and commercial buildings. It is versatile and can adapt to various construction methods. However, moisture sensitivity is a concern. Improper installation may lead to warping and reduced integrity over time. Awareness of these limitations is essential for contractors and builders. As the industry evolves, the need for more sustainable practices is becoming increasingly evident.

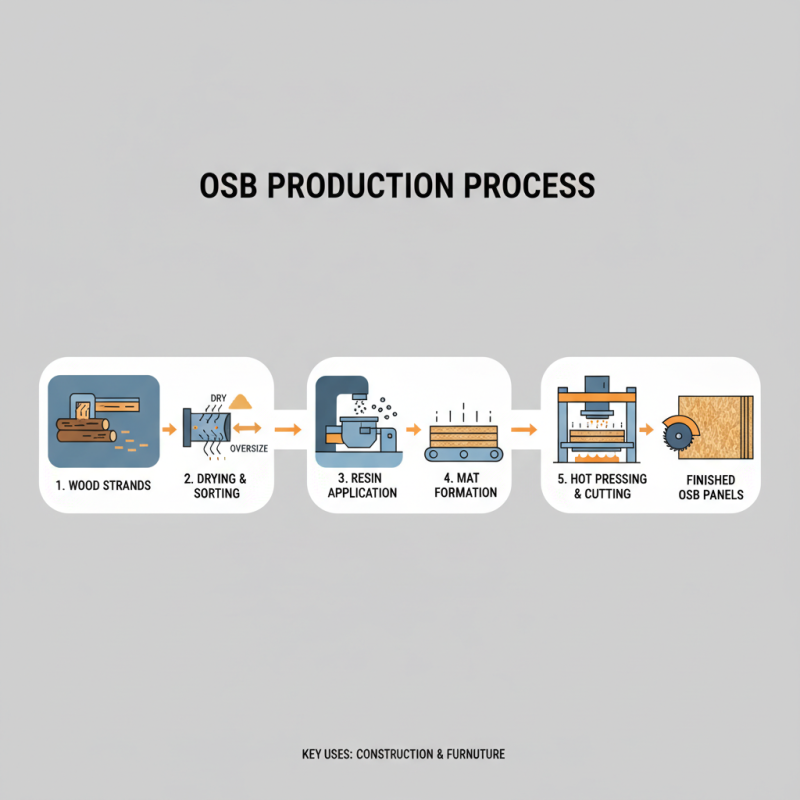

OSB board plywood is widely used in construction and furniture making. The manufacturing processes for OSB include several key steps that significantly influence the final product. First, wood strands are created from logs, ensuring they are uniform in size. This precision helps in achieving optimal strength and consistency.

Next, the strands are dried. This step is crucial to prevent moisture-related issues in the final product. According to industry reports, the moisture content should ideally be below 5% for best results. After drying, the strands are mixed with adhesives. This mixture is then arranged in layers, often oriented in different directions for enhanced stability.

The pressing process follows. High-pressure systems are used to bond the strands together, forming a dense panel. The heat and pressure conditions must be meticulously controlled. Any inconsistency can lead to weaker boards that may not meet structural standards. Quality control is essential. Some manufacturers still face challenges with edge bonding and delamination issues. These imperfections can affect the durability of the boards in real-world applications.

OSB board plywood has gained popularity in construction due to its versatility and structural integrity. Typically made from strands of wood, it offers a cost-effective solution for various applications. According to a report by the USDA Forest Products Lab, OSB can be more efficient than traditional plywood by utilizing smaller and less uniform wood materials.

In residential construction, OSB is commonly used for wall sheathing and flooring. Builders appreciate its strength and resistance to warping. It’s often chosen over plywood for subfloor applications, especially in areas with high moisture. Nonetheless, some experts note that OSB can absorb water, which may lead to swelling if not properly protected. This presents a challenge that builders must consider during planning.

Another common application is in commercial structures, where OSB serves as formwork for concrete. This allows for quicker installation and cost savings. However, OSB's performance can vary based on manufacturing quality. Inconsistencies in production can lead to unpredictable durability. Addressing these issues is crucial for ensuring safety and longevity in any construction project.

OSB board plywood has become popular in construction and furniture making. Its structure involves strands of wood, pressed and bonded together. This results in a robust, durable material. However, it is essential to consider both its advantages and disadvantages.

The advantages of OSB board plywood are notable. It is often more affordable than traditional plywood. According to industry reports, OSB can be up to 30% cheaper in some regions. This cost-effectiveness makes it appealing for large projects. Additionally, OSB is resistant to warping and shrinking. This makes it reliable for use in humid environments. Many builders appreciate these characteristics, but there are drawbacks as well.

On the downside, OSB board plywood has limitations. It can be less aesthetically pleasing than other materials. The textured surface might not be ideal for visible areas. Durability is another concern. OSB may not perform as well under extreme conditions. Some studies indicate that it can weaken when exposed to moisture over time. This raises questions about longevity. More reflective thinking is necessary when choosing materials for projects. Quality and appearance should not be overlooked.

| Dimension | Description |

|---|---|

| Material | Oriented Strand Board (OSB) is made from strands of wood and adhesive, providing strength and durability. |

| Uses | Commonly used in construction for flooring, walls, and roofs, as well as in furniture design. |

| Advantages | Cost-effective, strong, and resistant to warping and cracking under typical conditions. |

| Disadvantages | Can be susceptible to moisture damage if not properly sealed; may emit VOCs. |

| Sustainability | Made from fast-growing trees, making it a more sustainable option compared to traditional plywood. |

When comparing OSB board plywood with other wood products, several factors stand out. OSB, or oriented strand board, is made from strands of wood. It is engineered for strength and durability. Reports indicate that OSB can be 20% stronger than traditional plywood under similar dimensions. This quality makes it a popular choice in construction.

However, OSB has its downsides. It tends to absorb moisture quickly, which can lead to swelling and warping. Plywood, on the other hand, often has better resistance to moisture but can be more costly. Studies show that while OSB is cheaper upfront, its lifespan may be shorter than plywood in humid environments.

Tips: When choosing between OSB and plywood, consider the local climate. For dry areas, OSB can be a cost-effective choice. Conversely, for damp regions, investing in plywood might save on replacement costs down the line. Always weigh the benefits against your specific application. Be aware that over time, OSB’s performance in high moisture settings can be underwhelming.