Leave Your Message

-

Whatsapp

-

Whatsapp

Choosing the right OSB structural beams for your project is crucial. In recent years, the use of OSB continues to grow in construction. A report from the Engineered Wood Association indicated that OSB market demand rose by 25% in the last five years. This trend reflects the material’s affordability and reliability.

Experts emphasize the significance of proper selection. According to Jane Smith, an industry leader, "The right OSB structural beams can make or break a project." Selecting beams that fit specific requirements is essential. For example, factors like load-bearing capacity and environmental conditions cannot be overlooked.

However, some builders still underestimate these aspects. Choosing beams without proper consultation can have costly consequences. Therefore, understanding your project’s needs is vital. Carefully evaluating your options will lead to successful outcomes. Remember, mistakes in this area can lead to structural failures. Take the time to research and consult professionals.

OSB structural beams, or oriented strand board beams, are critical components in many construction projects. They are more than just wood; they are engineered products made from thin strands of wood. This design gives them strength and durability, which is essential for supporting structures. OSB beams are lighter than traditional lumber. This makes them easier to handle and install, especially in larger projects.

One of the key characteristics of OSB beams is their resistance to warping and shrinking. Unlike solid wood, they maintain their shape over time. This quality helps reduce maintenance issues in the long run. However, it's important to consider that not all OSB is created equal. Some varieties may not be suitable for high-moisture environments. Always evaluate your project's specific needs before making a choice.

Another benefit is cost efficiency. OSB beams are typically less expensive than solid wood beams. However, be cautious of opting for the cheapest options. Lower-quality OSB might compromise structural integrity. It's essential to strike a balance between cost and performance. Always ask questions and do thorough research to ensure you choose the best option for your build.

When selecting OSB structural beams, understanding

load-bearing capacity is crucial. Different projects have varying needs.

For a residential building, your beams may need to support heavier loads than in simple shed construction.

Consider the weight of materials and the purpose of the structure. This consideration ensures

safety and stability.

Dimensions also play a crucial role. Standard sizes might not fit all projects. Always measure your space

accurately. Some designs may require longer or wider beams. Think about the span distance and how it impacts

beam selection. A beam that looks adequate on paper may not perform well under real-life conditions.

It’s essential to revisit your initial calculations. Mistakes can happen,

and they can be costly. Double-checking your requirements with structural experts may clarify any uncertainties.

Building with the right dimensions and load capacity in mind makes the difference between

success and failure. Each decision impacts the overall

integrity of your project.

When selecting the right grade and thickness of OSB beams, consider your project's specific needs. OSB, or oriented strand board, comes in various grades. These grades cater to different applications. Not all grades are suitable for every project. You must assess the intended use. Structural applications often require high-grade OSB for better load-bearing capacities.

Thickness plays a crucial role in strength. Thicker OSB beams can support more weight. Standard thicknesses range from 1/2 inch to 1 inch or more. Choosing a thicker beam might add cost. However, it can prevent potential failures in the structure. Evaluate your design and the loads it will bear.

Tip: Always check the manufacturer's specifications for grading. This helps ensure you choose the correct grade. Tip: If in doubt, consult a professional for advice. Sometimes, what seems like a minor detail can lead to major issues. The right thickness could save time and resources later. Don't rush this decision; it affects safety.

When selecting OSB structural beams, moisture is a crucial factor. OSB, or oriented strand board, can be sensitive to humidity and water. Data shows that untreated OSB can lose strength significantly when exposed to moisture. According to a study by the APA – The Engineered Wood Association, moisture absorption can reduce the load-carrying capacity of OSB by up to 50%.

Treatment considerations are essential. Using pressure-treated OSB can prevent decay and insect damage. However, pressure-treated wood may contain chemicals that impact its performance. It is important to know that not all treatments are equal. Some may release volatile organic compounds (VOCs) that can harm indoor air quality. The choice of treatment method should depend on the specific environmental conditions of your project site.

Additionally, site conditions play a significant role. Areas with high humidity or frequent rainfall should use higher-grade materials. Many builders overlook the importance of local climate when making their selections. This oversight could lead to structural issues later on. It’s critical to assess these environmental factors carefully before making a decision.

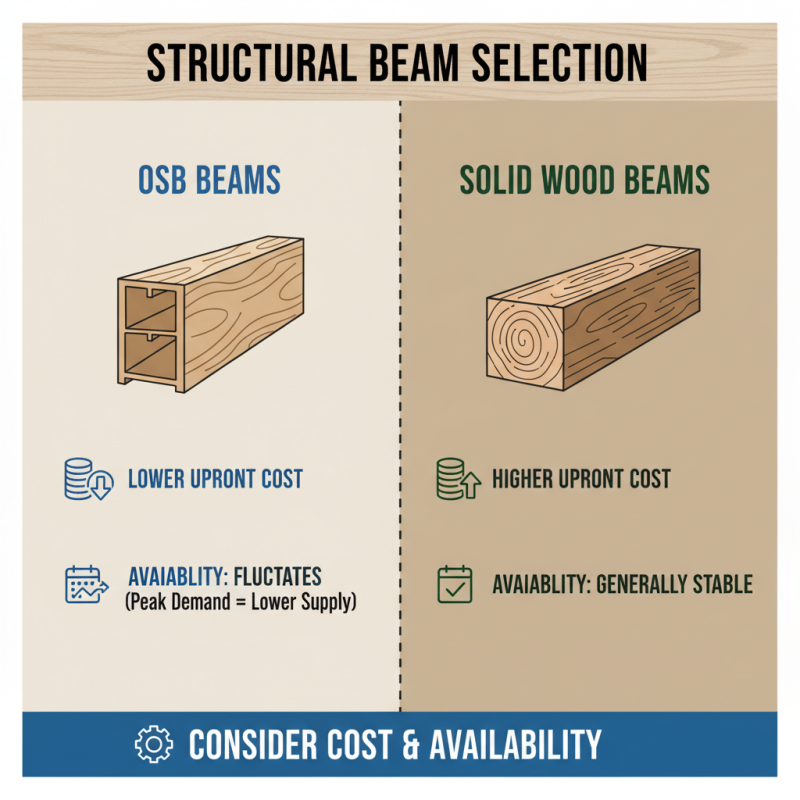

When selecting structural beams, cost and availability are key factors. OSB beams typically offer a lower upfront cost compared to solid wood alternatives. For many projects, this makes OSB appealing. However, price should not be the only consideration. Availability can fluctuate, especially during peak seasons. OSB supply might diminish when demand surges. This can lead to delays and increased costs.

On the other hand, alternatives like laminated veneer lumber (LVL) may be pricier, yet they come with benefits. Their strength and durability often outweigh the initial costs. Availability of LVL can be more stable, ensuring projects stay on schedule. Builders should assess local markets for supply. Understanding these dynamics is critical.

Choosing the right material requires reflection. Cost savings can be tempting, but long-term implications matter. Be mindful of strength and durability as well. Such considerations not only impact immediate costs but also the project’s lifespan. Each choice comes with its trade-offs.