Leave Your Message

-

Whatsapp

-

Whatsapp

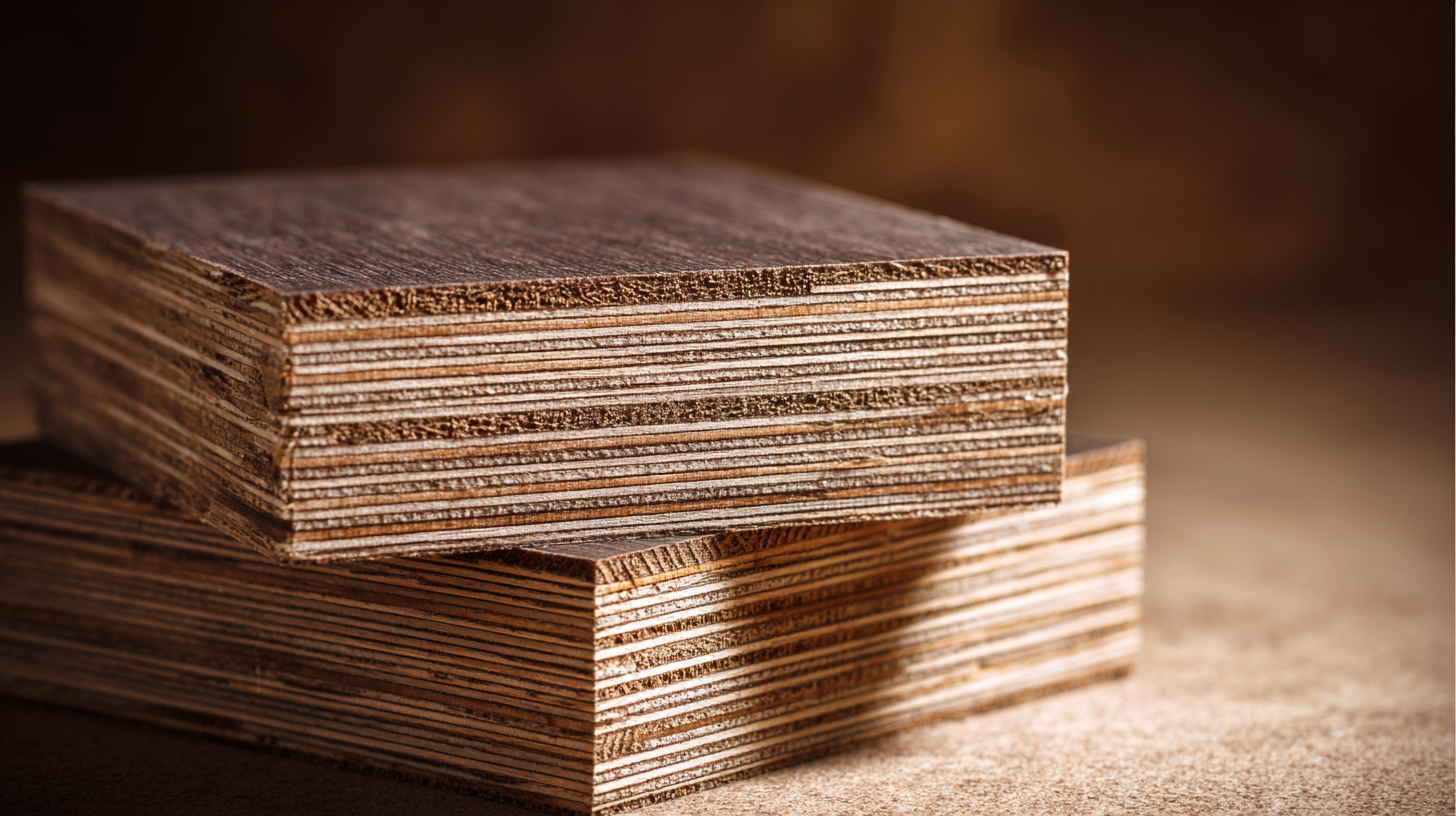

In the realm of construction materials, choosing the appropriate Film Faced Birch Plywood is crucial for ensuring strength and durability in various projects. According to a recent market analysis conducted by Smithers Pira, the global demand for plywood, particularly for construction purposes, is expected to reach approximately 15 million cubic meters by 2025. Film Faced Birch Plywood, prized for its superior bending strength and durability, stands out as an ideal choice for formwork and other structural applications. With its phenolic film surface offering enhanced resistance to moisture and wear, this type of plywood has become increasingly popular in the construction industry. While making a selection, it is essential to consider factors like thickness, adhesive type, and surface quality to meet the specific demands of your projects and align with industry standards, ensuring that your construction undertakings are both reliable and sustainable.

When selecting the appropriate film faced birch plywood for construction projects, understanding the different grades available is crucial. Birch plywood typically comes in several grades, including A, B, C, and D.

Grade A is the highest quality, featuring a smooth surface with minimal imperfections, making it ideal for applications where appearance is important. This grade offers excellent strength and durability, making it suitable for high-end construction work.

Grade B plywood has slightly more imperfections than Grade A, but it still maintains a good level of strength and durability. It's often used in scenarios where the aesthetic appeal is less critical, yet high performance remains a priority. Grades C and D have increasingly visible defects but can still serve as effective solutions for less demanding applications. Understanding these grades helps in making informed choices that balance both structural integrity and budget considerations, ensuring that the selected plywood meets the specific demands of your construction projects.

When selecting film faced birch plywood for construction projects, evaluating its strength characteristics is crucial. Birch plywood is renowned for its superior strength-to-weight ratio, making it an ideal choice for demanding applications. According to industry reports, birch plywood exhibits an average bending strength of approximately 30 MPa, which is significantly higher than that of alternative materials like pine or poplar. This strength allows it to withstand heavy loads and resist deformation, making it suitable for formwork and structural applications.

Durability is another vital consideration. The film facing on birch plywood enhances its resistance to moisture and abrasion, which is essential for construction environments. A study published by the Plywood Association indicates that film faced birch plywood can maintain its structural integrity in wet conditions, retaining over 90% of its strength even after prolonged exposure to moisture. This durability drives its popular use in commercial and industrial applications, where resilience against environmental factors is paramount. By understanding these strength characteristics, builders can make informed decisions that will ensure the longevity and performance of their construction projects.

When selecting film faced birch plywood for construction projects, assessing durability factors is crucial to ensure optimal performance in various environments. Weather resistance is one of the primary characteristics that defines the longevity of plywood. According to a report by the American Plywood Association, plywood that undergoes rigorous testing for moisture content and weather exposure demonstrates a significant decrease in deterioration when properly sealed, showing a lifespan increase of up to 50% compared to untreated options. This highlights the importance of choosing high-quality film faced plywood with superior protective coatings to withstand harsh outdoor conditions.

Moreover, longevity is not solely dependent on initial weather resistance but also involves the material's structural integrity over time. Studies indicate that birch plywood offers exceptional strength-to-weight ratios, making it a preferred choice in demanding construction applications. The The International Journal of Advance Research in Science and Engineering points out that birch plywood can sustain loads of over 1000 N/mm², making it durable enough for heavy-duty use. Selecting the right film faced birch plywood, therefore, involves considering both its resistance to environmental factors and its inherent mechanical properties to ensure lasting performance in your construction projects.

When selecting film faced birch plywood for construction projects, the choice of surface treatment is crucial for enhancing both strength and durability. Recent studies underscore the importance of surface modifications in improving material performance. For instance, research on thermoplastic composites emphasizes that surface oxidation techniques can significantly enhance interface adhesion and overall functionality. This insight can be applied to plywood, where appropriate surface treatments, such as plasma or heat treatments, could bolster the inherent strength of the plywood while ensuring a higher quality finish.

Moreover, surface roughness has been shown to affect the performance of various materials, including those used in advanced applications like quantum computing. Optimizing the surface quality of film faced plywood could similarly mitigate wear and tear, thereby increasing longevity and performance in demanding construction environments. Furthermore, technologies such as Plasma Electrolytic Oxidation (PEO) illustrate that pre-treatment methods can profoundly impact the durability of surface finishes. As the construction industry increasingly values sustainability and performance, investing in the right surface treatments for birch plywood will not only yield functional advantages but also contribute to the longevity of the structures they help create.

| Dimension | Thickness (mm) | Load-Bearing Capacity (N) | Water Resistance | Surface Finish | Recommended Use |

|---|---|---|---|---|---|

| 2440 x 1220 | 18 | 5000 | High | Smooth Phenolic | Formwork, Sheathing |

| 2500 x 1250 | 20 | 6000 | Medium | Textured Melamine | Furniture, Cabinetry |

| 3000 x 1500 | 12 | 3500 | Low | Unfinished | Interior Applications |

When selecting film faced birch plywood for construction projects, determining the appropriate thickness is crucial for balancing weight and structural integrity. Thicker plywood generally offers enhanced strength and rigidity, making it suitable for heavy-duty applications where load-bearing capabilities are essential. For instance, using 18mm or 21mm thick plywood can significantly increase the stability of structures subjected to significant stress. However, this increased thickness also adds weight, which can complicate transportation and handling on-site.

When selecting film faced birch plywood for construction projects, determining the appropriate thickness is crucial for balancing weight and structural integrity. Thicker plywood generally offers enhanced strength and rigidity, making it suitable for heavy-duty applications where load-bearing capabilities are essential. For instance, using 18mm or 21mm thick plywood can significantly increase the stability of structures subjected to significant stress. However, this increased thickness also adds weight, which can complicate transportation and handling on-site.

On the other hand, opting for thinner plywood can minimize weight, making it easier to work with, particularly in projects where ease of installation and maneuverability are priorities. For applications that require less strength, such as interior partitions or temporary structures, thinner options like 12mm or 15mm can provide sufficient support without compromising the overall efficiency of the construction process. Ultimately, the choice of thickness should be guided by the specific demands of the project, ensuring a perfect blend of weight management and the requisite durability for long-lasting results.