Leave Your Message

-

Whatsapp

-

Whatsapp

Plastic Laminated Plywood has become a popular choice in construction and design. Its versatility and durability cater to various projects. According to a recent industry report by the Global Plywood Association, the demand for Plastic Laminated Plywood is expected to increase by 15% annually. This growth reflects its rising importance in both residential and commercial sectors.

Expert Jane Smith, a leading figure in the plywood industry, emphasizes the significance of proper selection. "Choosing the right Plastic Laminated Plywood can make or break a project," she states. Her insight highlights the critical nature of making informed decisions. Factors like thickness, surface finish, and resistance to moisture should be carefully considered.

While many may focus solely on aesthetics, overlooking performance characteristics can lead to regrets. Selecting the wrong type could compromise the integrity of a project. Ensuring the right balance between style and functionality requires thought and research.

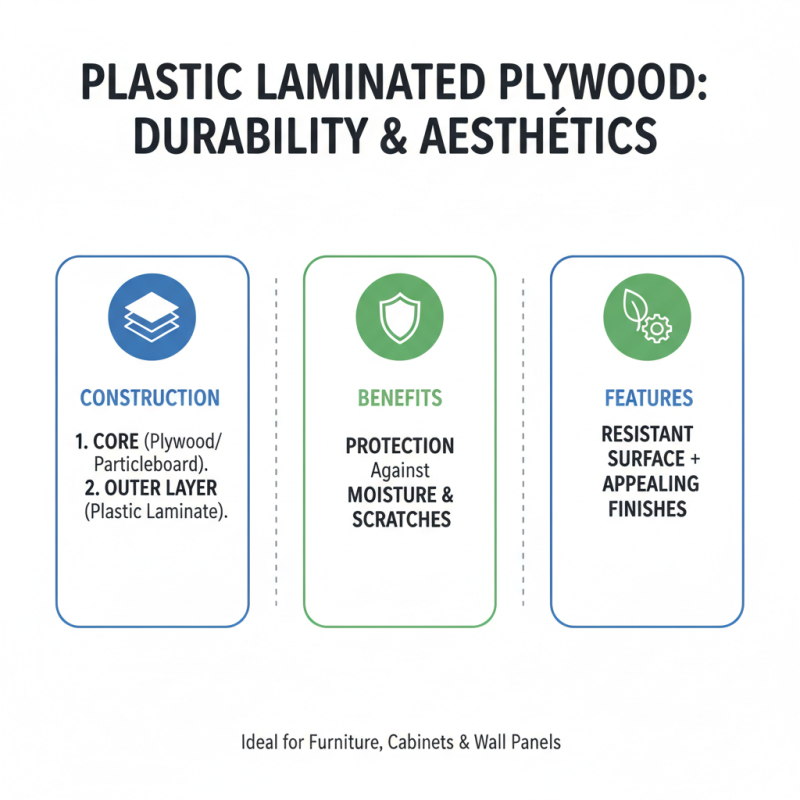

Plastic laminated plywood combines durability and aesthetics. Its construction typically includes a core made from plywood or particleboard. This core is then layered with a plastic laminate. This outer layer provides a protective surface against moisture and scratches.

Understanding the laminate's composition is crucial for project success. Different materials can affect strength and finish. Plywood cores are often stronger than particleboard. However, some may prefer particleboard for lightweight needs. The thickness of the laminate also plays a role. Thicker laminates usually provide better durability but add weight.

When selecting your plywood, examine the laminate's texture and color. Smooth, glossy finishes can enhance visual appeal. However, they may show fingerprints more easily. Consider the project's requirements. Is it for heavy use or decorative purposes? Every choice in composition impacts the final result.

Evaluating the durability of plastic laminated plywood is essential for any project. This material offers a protective layer that enhances resistance to scratches and moisture. However, not all laminates are created equal. Some may fade or wear out faster under extreme exposure to sunlight. It's crucial to consider the environment where the plywood will be used.

Environmental factors play a significant role in the longevity of laminated plywood. High humidity can cause delamination over time. Additionally, exposure to chemicals can weaken the laminate. Choosing a product that has high resistance to these elements is vital. The integrity of your project relies on the plywood's ability to withstand these challenges.

Reflecting on past projects can offer valuable insights. Maybe you chose a less durable option and faced issues later. Learning from these experiences can guide future choices. Always ask questions about the laminate's specifications. Gathering information can prevent mishaps and ensure a more successful outcome.

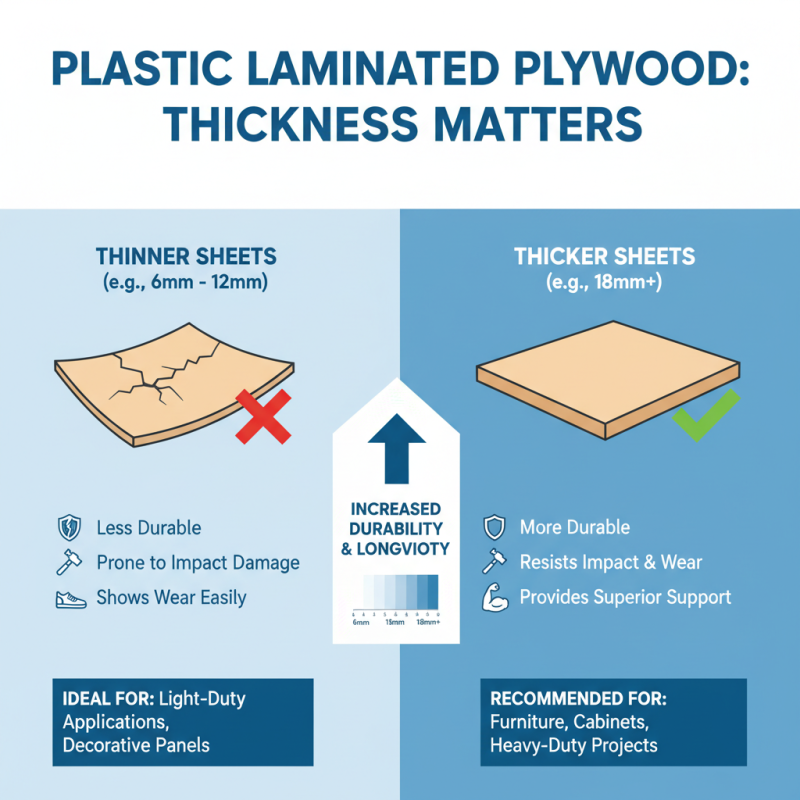

When choosing plastic laminated plywood, thickness matters significantly. Thicker sheets offer more durability. They withstand impact and resist wear better than thinner options. For heavy-duty projects, like furniture or cabinets, a thickness of at least 18mm is often ideal. It provides ample support and longevity, which is crucial for high-use items.

On the other hand, thinner plywood can work well for lighter projects. Options around 9mm or 12mm are suitable for decorative surfaces or less-intensive applications. They are easier to handle and cut, making them a favorite among DIY enthusiasts. However, one must consider their limitations carefully. They may not support heavy weights, leading to potential issues down the line.

Ultimately, assessing your project's needs is vital. Sometimes, it's wise to test different thicknesses before committing. Each project has unique demands that could influence your choice. A balance between aesthetics and functionality leads to better results. Reflecting on your choices can provide clarity in selecting the right material for your needs.

When selecting plastic laminated plywood, the surface finish plays a crucial role in aesthetics. The texture, gloss, and color can transform any project. A smooth finish may bring a modern feel, while a textured surface can add warmth or character. Glossy finishes often reflect light, creating a vibrant look, but they might show fingerprints. Matte surfaces provide a more understated appeal, though they may not be as easy to clean.

Tips: Pay attention to color trends. For a cozy ambiance, consider earthy tones. Bright colors can energize a space. Test samples in natural light to see how they interact with other elements.

Choosing the right finish is not always straightforward. Some options may seem appealing but don’t suit the project’s environment. For instance, a high-gloss finish might look stunning but could be impractical for heavy-use areas. Reflecting on how the surface will wear over time is essential. Will it hold up under daily use?

Remember, imperfections can add character. Embrace the unique marks that are part of the material’s life. They tell a story. Each project becomes a personal statement; make sure the surface reflects that intention.

When selecting plastic laminated plywood, cost-effectiveness is crucial. Reports indicate that plastic laminated plywood can be 15-20% cheaper than traditional materials over time. The initial investment may appear higher, but the durability and low maintenance costs can lead to substantial savings.

Choosing the right thickness is vital. Thicker plywood can handle more stress and last longer. However, it typically costs more. Many users overlook this, focusing solely on price. This can lead to regret later when their plywood warps or cracks.

Tips: Always calculate the total cost of ownership. Include maintenance and replacement expenses. Selecting a lower-priced option now may increase long-term costs. Consider aesthetics and functions. The wrong choice may not only affect budget but also impact project quality. High-quality plywood often yields better results, despite its price.