Leave Your Message

-

Whatsapp

-

Whatsapp

When it comes to construction, selecting the right materials is crucial. Joists Timber plays a vital role in structural integrity. Experts emphasize this importance. John Smith, a renowned timber specialist, states, "Quality joists timber can make or break a building project." This sentiment echoes throughout the construction industry.

Many builders overlook the significance of choosing the best Joists Timber. Each option has its pros and cons. Some timber types may warp or twist over time. Others might lack the necessary strength for specific applications. It's essential to weigh these factors carefully. A well-informed decision can lead to a more durable structure.

In this guide, we will explore the top ten Joists Timber options available today. The focus will be on durability, cost, and overall performance. Understanding the available choices ensures that your construction is secure and lasting. Quality matters; great timber selections can enhance your projects significantly.

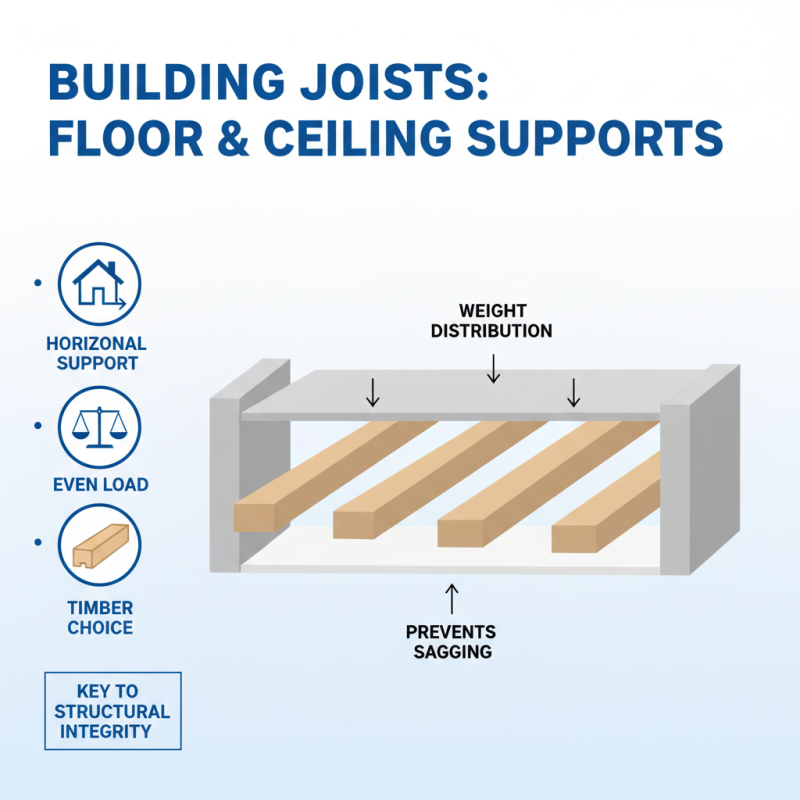

Joists are critical components in building construction. They are horizontal supports that hold up floors and ceilings. Understanding their function is key to ensuring structural integrity. Joists distribute weight evenly, preventing sagging and damage to the construction above. They come in various materials, but timber joists have become a popular choice for many builders.

When selecting joists, consider the type of wood. Lighter woods can be easier to handle but may not provide the same strength. Heavier woods, while sturdy, can be more challenging to work with. The size of the joists impacts load capacity. Ensure you choose appropriate dimensions for your project requirements.

Tip: Always check local building codes before purchasing materials. They may have specific regulations about joist sizes and materials. Another tip is to inspect wood for defects before installation. Cracks and knots can weaken the structure. Avoid rushing this process. It can save you time and hassle later in the construction phase. Keep in mind, the right choice in joists can greatly affect the building's lifespan.

When it comes to selecting timber for joists, various types exist, each with unique properties. Softwood options, such as pine and spruce, are popular due to their availability and cost-effectiveness. These woods are generally lightweight and easy to work with. However, they may not offer the same durability as hardwoods. For long-lasting structures, hardwoods like oak and maple present a solid choice. Their density provides excellent strength but at a higher price point.

Engineered wood products, like laminated veneer lumber, can also be viable alternatives. They often outperform natural wood in terms of stability and load-bearing capacity. But these materials may come with a different set of environmental concerns. The manufacturing process involves adhesives that could impact health. Understanding these factors is essential for making informed choices.

The wood you select should align with your project goals. Considerations like weight, cost, and climate can influence your decision. It's important to reflect on your needs deeply. Sometimes, what seems like the best choice may not be suitable for your specific situation. Balancing performance and sustainability often requires careful thought, especially for long-term projects.

When considering timber options for joists, the material’s features and benefits are crucial. Timber is often chosen for its natural strength and aesthetic appeal. Various types of wood can offer different qualities. For instance, softwoods like pine are lighter and easier to work with. They tend to be more affordable and suitable for many construction projects. However, they may not provide the same durability as hardwoods.

Hardwoods like oak and maple are known for their robustness. These woods can handle heavy loads and resist wear over time. But they also come with a higher price tag and can be more challenging to source. Environmental factors play a role, too. Timber must be treated properly to avoid issues like warping or insect damage. It’s essential to consider sustainability. Some woods are harvested in a more eco-friendly manner, which can impact choice.

While choices are abundant, reflecting on the specific needs of your project is vital. Not all timber will suit every structure. Cost, weight, and longevity matter. Designers and builders should assess both aesthetic and practical aspects. Balancing beauty with function often leads to better outcomes.

Choosing the right timber joists is essential for any construction project. Many factors come into play. The first consideration is the type of wood. Softwoods, like pine, are often chosen for their affordability. They are lightweight and easy to work with. However, they may not be the best choice for high-load areas. Hardwoods, on the other hand, provide excellent strength. Yet, they can be significantly more expensive.

The dimensions of the joists are equally critical. A thicker joist may offer more support but adds weight. This can complicate transportation and installation. Always consider the span it needs to cover. Longer spans require deeper joists. Also, think about the moisture content. High moisture can lead to warping or decay over time.

It’s important to factor in local climate conditions too. Humidity can affect timber performance. Lastly, don’t ignore the sourcing of the timber. Sustainable options may cost more but benefit the environment. Each of these choices requires reflection. The perfect joist may not exist, but informed decisions can lead to better outcomes.

This chart displays the top 10 timber options for joists based on their average strength rating and cost-effectiveness for construction projects. The X-axis represents different timber types, while the Y-axis showcases their strength rating (ME tested) and average cost.

When installing timber joists, proper techniques can significantly enhance their performance and longevity. Industry reports indicate that incorrectly installed joists can lead to issues like sagging or cracking, affecting the structural integrity. Ensure your installation process includes adequate spacing; a gap of 16 inches is often recommended. Using a level during placement is crucial to avoid uneven support.

Regular maintenance of timber joists is essential. Inspections should occur at least twice a year. Check for signs of moisture damage or pest infestations. Pay attention to any discoloration or soft spots in the wood. It's worth noting that studies show timber systems exposed to high humidity require more frequent assessments compared to drier environments. Implementing protective treatments can extend the lifespan of joists, but choose wisely—the right solution depends on your specific conditions.

Timber joists need proper ventilation to prevent mold growth. Maintain airflow in enclosed spaces to help manage humidity levels. Remember, infrequent maintenance can lead to costly repairs down the line. It’s a tough reminder: taking shortcuts now may mean larger issues later.

| Timber Type | Strength Grade | Weight (lbs/ft) | Typical Span (ft) | Moisture Content (%) | Price per Square Foot ($) |

|---|---|---|---|---|---|

| Pine | Lumber Grade 2 | 3.5 | 12 | 12 | 2.50 |

| Oak | Lumber Grade 1 | 4.0 | 14 | 10 | 3.75 |

| Spruce | Lumber Grade 2 | 3.0 | 10 | 15 | 2.30 |

| Douglas Fir | Lumber Grade 1 | 4.5 | 16 | 12 | 3.50 |

| Red Cedar | Lumber Grade 2 | 2.5 | 10 | 10 | 4.00 |

| Teak | Lumber Grade 1 | 5.0 | 18 | 8 | 5.50 |

| Mahogany | Lumber Grade 1 | 4.8 | 15 | 10 | 6.00 |

| Bamboo | High Strength | 2.2 | 12 | 8 | 3.25 |

| Larch | Lumber Grade 2 | 4.2 | 14 | 12 | 3.10 |

| Hemlock | Lumber Grade 2 | 3.2 | 11 | 15 | 2.90 |